Maintaining optimal air quality in industrial environments is essential for safeguarding the health and productivity of workers. While both air filtration and ventilation systems play pivotal roles in purifying indoor air, they function differently and are suited to distinct applications. This article delves into the fundamental differences between industrial air filtration and ventilation, providing insights to help you choose the most appropriate system for your facility.

Understanding Industrial Air Quality Management Systems

In industrial settings, air quality management is critical due to the presence of airborne pollutants that can have long-term health implications. Industrial air treatment systems, encompassing both filtration and ventilation technologies, are engineered to mitigate these risks by removing contaminants and ensuring a healthier work environment.

Industrial Air Filtration and Ventilation: A Comparative Overview

Although often conflated, air filtration and ventilation are distinct processes with unique mechanisms and benefits. Air filtration systems cleanse and recirculate the same indoor air by removing particulates and pollutants, whereas ventilation systems replace indoor air with fresh outdoor air, diluting indoor contaminants.

Detailed Examination of Air Filtration Systems

Air filtration systems operate by capturing airborne particles at their source using specialized filters, such as HEPA or activated carbon filters. These systems are adept at removing dust, fumes, and microscopic pollutants, releasing purified air back into the industrial environment. Importantly, air filtration does not introduce new air but continuously cleanses the existing indoor air.

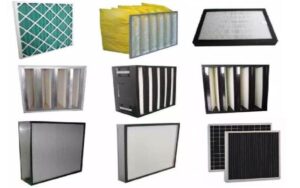

Types of Industrial Air Filtration Units

- Ambient Air Filtration Units: These units can function independently or alongside other air capture systems, effectively reducing airborne contaminants throughout the facility.

- Portable Air Filtration Units: Designed for mobility, these units are placed directly in specific work areas to target and eliminate pollutants at the source.

In-Depth Look at Air Ventilation Systems

Air ventilation systems facilitate the exchange of indoor air with outdoor air, enhancing indoor air quality by diluting pollutants. These systems are essential in environments where stagnant air can accumulate harmful substances or in facilities requiring fresh air for comfort and safety.

Categories of Industrial Air Ventilation

- Spot Ventilation (Local Ventilation): This method involves the removal of polluted air from specific areas using equipment like exhaust fans or hoods. It is commonly employed in zones with high concentrations of contaminants, such as welding stations or chemical processing areas.

- Whole-Building Ventilation: This approach replaces the air throughout the entire facility, ensuring consistent air quality by introducing fresh air and expelling stale air.

Comparative Analysis: Air Filtration vs. Air Ventilation

To assist in selecting the appropriate system, the following table outlines key differences between air filtration and air ventilation:

| Aspect | Air Filtration | Air Ventilation |

|---|---|---|

| Primary Function | Removes pollutants from indoor air | Replaces indoor air with outdoor air |

| Air Exchange | Recirculates the same air after purification | Introduces fresh air, expels stale air |

| Pollutant Removal | Effective at capturing particulates, dust, fumes | Dilutes pollutants but does not remove them |

| Energy Efficiency | Generally energy-efficient due to air recirculation | May increase energy costs due to heating/cooling incoming air |

| Ideal Use Cases | Environments with high levels of airborne contaminants | Facilities needing fresh air or dilution of gases |

Selecting the Optimal Air Quality Solution for Your Facility

The choice between air filtration and ventilation systems hinges on specific operational needs and environmental factors. Ventilation systems are advantageous in settings where the primary goal is to introduce fresh air and dilute indoor pollutants, particularly when the outdoor air quality is high. However, they may not effectively eliminate certain contaminants like chemical vapors or fine particulates.

Conversely, air filtration systems are ideal for environments where the removal of hazardous particles is critical. These systems efficiently capture and neutralize pollutants but do not provide fresh air circulation.

Integrating Filtration and Ventilation for Enhanced Air Quality

In many cases, a combination of both systems yields the best results. Integrating air filtration with ventilation can ensure the removal of harmful particulates while also providing the benefits of fresh air circulation, leading to a safer and more comfortable industrial environment.

Conclusion

Understanding the distinct functions and benefits of air filtration and ventilation systems is crucial for making informed decisions about industrial air quality management. By evaluating the specific needs of your facility, you can implement the most effective solutions to protect worker health and maintain regulatory compliance.

Explore Advanced Air Filtration Solutions

For facilities seeking cutting-edge air purification technologies, KOINfilter offers a range of advanced air filtration systems designed to eliminate even the most minute pollutants. Our expertise in industrial air quality ensures that you receive tailored solutions to meet your unique operational requirements.