Currently, most countries use the requirements for vacuum cleaner filters in IEC and ASTM as standards. IEC is the International Electro Technical Commission, and ASTM is the American Society for Testing and Materials. Both of them represent international standards. Many countries around the world adopt their standards.

About vacuum cleaners

In August 1901, an Englishman named Booth applied for a vacuum cleaner patent, the world’s earliest prototype of a vacuum cleaner.

Since then, vacuum cleaners have gone through decades of development, from having no brush heads to being equipped with brush heads suitable for various occasions, from being powered by fuel to being powered by electricity, from being heavy and requiring a horse-drawn carriage to pulling it to being easily moved and operated by one person.

In Western countries in the mid-20th century, vacuum cleaners gradually entered the middle class from luxury goods and became high-end daily necessities. With improving living standards, these home appliances are being used increasingly.

Especially in recent years, vacuum cleaners and sweepers have entered the homes of ordinary people in large numbers and have become essential household appliances.

At the same time, there are many top vacuum cleaner manufacturers worldwide, such as Dyson, Puppy, etc. Vacuum cleaner technology is also changing rapidly.

Vacuum cleaner filters

The old-fashioned vacuum cleaner is a “dust generator.” One end sucks in various debris, dust, hair, etc., and the other end emits fine dust.

People began to realize this problem and installed air filters in vacuum cleaners to solve this problem. So, this filter has become an essential part of the vacuum cleaner. It can prevent the vacuum cleaner from causing secondary pollution.

Many companies are engaged in producing Vacuum cleaner filters. When faced with such emerging products, they mostly produce them according to specific user requirements without understanding the relevant standards.

We all know that in the industrial or commercial field, there are many standards for air filters, such as EN779, EN1822, MERV, ISO16890, and so on.

Let me talk about the standards for vacuum cleaner filters.

Current standards

As the vacuum cleaner industry develops and matures, the standards for this product type gradually develop and become complete.

I made a table summarizing international and national standards for vacuum cleaners and sweepers.

| Title | Standard | Remark |

| Safety of household and similar electrical appliances, special requirements for wet and dry vacuum cleaners for industrial and commercial use. | IEC 60335-2-69 | International standard |

| Safety of household and similar electrical appliances, special requirements for wet and dry vacuum cleaners for industrial and commercial use. | GB 4706.93 | China standard, Equivalent adoption IEC 60335-2-69 |

| Surface cleaning appliances, performance test methods for dry cleaning robots for household and similar purposes. | IEC/ASTM 62885-7 | International standard |

| Surface cleaning appliances-part2, performance test methods for dry cleaning robots for household and similar purposes. | IEC 62885-2 | International standard |

| Surface cleaning appliances-part2, performance test methods for dry cleaning robots for household and similar purposes. | GB/T 38048.2 | China standard, Equivalent adoption IEC 62885-2 |

| Standard test method for testing initial and graded filtration efficiency of vacuum cleaners. | ASTM F1977 | USA standard |

The above standards include general requirements, special requirements, and performance test methods for vacuum cleaners and sweeping robots.

As can be seen from the table, international standards mainly fall into two categories: IEC and ASTM. IEC standards are from the International Electrotechnical Commission, the world’s earliest non-governmental international electrotechnical standardization organization.

Countries such as Europe, Australia, and China follow IEC standards; China adopts them equivalently, and other countries adopt them with modifications.

Therefore, below, I will focus on the standards of IEC and ASTM.

General requirements and special requirements of IEC and ASTM

In these two standards, some general and special requirements for vacuum cleaners are stated respectively.

General requirements

IEC 60335-1 is a general requirement for household and similar electrical appliances; that is, all household appliances should meet, mainly regarding electrical safety regulations.

Special requirements

Special requirements are made for a specific type of product. For example, IEC 60335-2-2 mainly targets vacuum cleaners and water-suction cleaning appliances, and IEC 60335-2-69 mainly targets wet and dry vacuum cleaners for industrial and commercial use.

The test items involved in the two standards are consistent with the general requirements. Only the specific test methods and requirements differ depending on the product type.

Requirements for air filters in standards

Regarding filtration performance, IEC 60335-2-69 sets out requirements for vacuum cleaners used in hazardous environments. According to different hazard levels, it sets out requirements for testing filter materials, filter elements, and filtration efficiency of the entire machine.

Classification of hazard levels

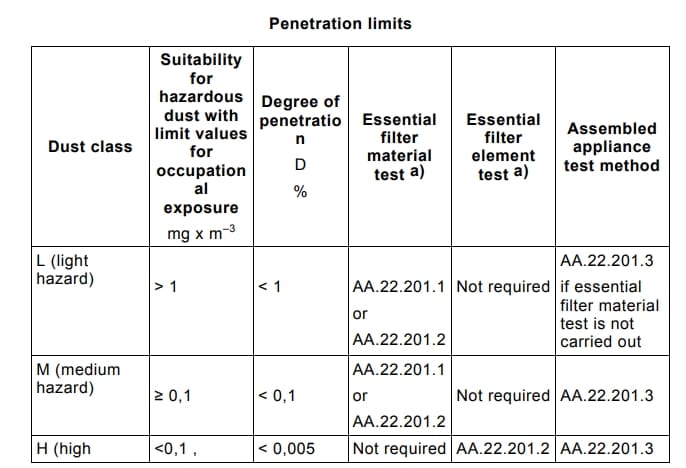

IEC defines hazard levels by the amount of hazardous dust with occupational exposure limits in mg/m3; the details are as shown below:

Testing requirements

L and M hazard levels require testing the filter material and the complete machine. The filter material needs to be tested according to AA.22.201.1 or AA.22.201.2 provisions, and the complete machine must be tested according to the provisions of AA.22.201.3.

For hazard level H, the filter element and the whole machine are required to be tested. The filter element is tested according to the provisions of AA.22.201.2, and the entire machine needs to be tested according to the provisions of AA.22.201.3.

Moreover, the testing media of filter materials, filter elements, and complete machines are all different.

The filter material test medium is broad-spectrum quartz stone, the whole machine test uses polydisperse limestone, and the filter element test uses aerosols such as paraffin oil, DOP or NaCl.

Vacuum cleaner filter performance testing methods

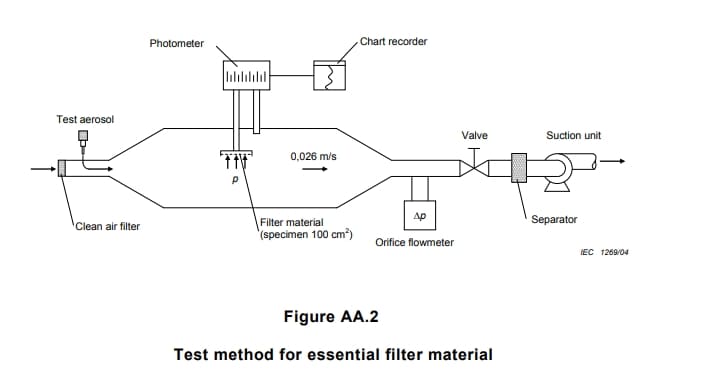

Similarly, the IEC also specifies performance testing methods for vacuum cleaner filters.

Test method for vacuum cleaner filter

Performance test methods for household dry vacuum cleaners are required by standards IEC 60312-1 and IEC 62885-2.

It stipulates the cleaning test methods for dry vacuum cleaners, including the dust removal effect on floors, carpets, walls, etc., the performance of dust collectors under dust load, and the filtration efficiency of vacuum cleaners, and test methods for mixed tests, including motion resistance, impact test, life test, noise, energy consumption, etc.

In terms of filtration efficiency, it only stipulates the test cover. It also states that the ASTM F1977 device can also be used to record the filtration efficiency results. There is no requirement for specific indicators of filtration efficiency.

Commercial vacuum cleaner filter

IEC62611 stipulates the performance test method for commercial vacuum cleaners, and the specific content is not much different from that of household vacuum cleaners.

What deserves attention is the “equivalent HEPA filtration level of the vacuum cleaner.” The main filter or primary filter needs to determine the most penetrating particle size in accordance with EN1822.

According to the measurement of graded filtration efficiency according to ASTM F1977, the MPPS efficiency is greater than 99.95%, which corresponds to HEPA H13 specified in EN1822. Vacuum cleaner emissions follow the methods specified in ASTM F2608.

ASTM F1977 specifies the initial and graded efficiency test methods for complete vacuum cleaners. The test aerosol specified in this standard is KCl after electrostatic neutralization, and the detector is a 6-channel discrete particle counter.

Sweeping robot filter

As a branch of vacuum cleaners, sweeping robots have individual standards such as IEC 62885-7, which mainly stipulate automatic navigation and cleaning capabilities.

There are no special requirements for filter elements and complete machine filtration efficiency, emissions, etc.

Here, I can understand that it can be carried out according to the relevant test requirements of vacuum cleaners.

Last summary

In the current standards, in terms of filtration performance, there are testing requirements for the filtration efficiency and emissions of the complete machine. Still, there are currently no specific index requirements.

In terms of vacuum cleaners used in commercial or toxic and harmful environments, the filtration level is required, which should reach the H12 level or even higher, given the hazards of secondary pollution.

Finally, I would like to add that more and more vacuum cleaner manufacturers are beginning to have requirements for filter resistance. They may have also noticed the impact of filter resistance on vacuum cleaner suction and energy consumption. It is expected that the next development direction will be competition with lower resistance.