From my observation, air filters are becoming increasingly important in the farming industry.

With the raging epidemic of PRRS in recent years, biosecurity has received more and more attention from breeding enterprises. Air filtration is an essential and effective way to deal with airborne diseases.

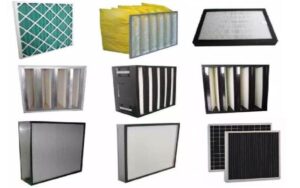

Many farms also have some problems when using air filters.

5 common problems about the Use of Air Filters in Swine Farms

1. Use low-grade air filtration products, such as MERV8 or G4 filter cotton, as the final filter.

2. Choosing an air filter that is fragile and not weather-resistant will cause the air filter to fail prematurely during transportation, installation, and use.

3. The wrong fan was selected for the air filtration system, resulting in insufficient ventilation in summer.

4. Only focusing on the filtration of the air inlet of the pig house ignores the importance of the air tightness of the building and the fresh air system of the pig house auxiliary room, resulting in unfiltered air entering the house.

5. The operation and maintenance of the air filtration system needs to be timely, and severely contaminated or blocked filters need to be replaced in time to ensure the ventilation volume and the safety of the filtration system.

Operation and maintenance not only focus on the air filter itself but also on the air tightness of the air filter wall, air filter room building, and the integrity of the fan inlet and outlet in the ventilation system.

Principles of epidemic prevention of air filters in swine farms

The primary purpose of using air filters in pig houses is to reduce the airborne transmission routes of some pathogenic microorganisms.

Studies have shown that PRRV can spread more than 9.1km through the air.

Some comparative experiments also show that the air filtration system can effectively reduce the spread of PPRSV.

Does the air filter directly filter pathogens?

Is it advisable to customize air filters of different sizes or varieties? Based on my industry experience, I do not recommend this. This is a misunderstanding,

The air filter does not directly filter viruses or bacteria. What it filters is the transmission medium of pathogens: dust particles or other aerosols.

The pathogen cannot be spread by autonomous flight and must be attached to a vector. The diameter of this medium in nature is usually 0.3 to 1 micron, so the air filter filters these 0.3 to 1 micron particles to intercept bacteria-carrying particles.

How to choose the right air filter for swine farms?

The ventilation conditions of pig farms are characterized by high temperature, high humidity, large air volume, low pressure, and high-level biosafety requirements, which place relatively stringent requirements on air filters.

Choose the proper filtration efficiency

After years of application worldwide, only F9 grade (MERV15-16) air filters can effectively cut off the airborne transmission of pathogens.

Because the filtration efficiency is too low (20% lower than F9), the F8 grade filter is only used as a transitional application in conventional low-risk environments.

Currently, all livestock industries in Europe and the United States use F9-level filters. In other countries, due to cost considerations, nearly 20% of farms are using F8-level filters.

The air filtration system is the last line of defense for the entire biosecurity and epidemic prevention system. If conditions permit, it is recommended that users use a high-level filtration system to remove pathogens as much as possible.

Users need to identify some parameters of filtration efficiency further. For example, when talking about filtration efficiency of 85%, what we need to understand is that this is only a relative accuracy.

The absolute accuracy is whether the filtration efficiency is for 0.3 microns or particles of other diameters.

Pay attention to air filter materials

Unlike civil, industrial, or medical applications, air filtration systems used in farms are exposed to large areas outdoors.

Due to factors such as sunlight, high humidity, high dust, high corrosion, and the use of low-energy fans in the farm, conventional air filters are not effective in the farm. The main manifestations are damage and air leakage during use, excessive wind resistance affecting the ventilation volume, disposal of discarded filters affecting the environment, etc.

Fiberglass, PP, and Composite fibers

Glassfiber

Conventional glass fiber filters are widely used indoors in the civil and medical industries, but they are not suitable for use in breeding environments due to their poor damage resistance and high wind resistance.

In the early days of the U.S. livestock industry, some farms used fiberglass filters, but they have now been basically eliminated.

PP fiber

Polypropylene fiber filter. Its filtration antibacterial performance is stronger than that of glass fiber. Still, its shortcomings of poor damage resistance and high wind resistance have made it out of use in the breeding industry.

Composite fibers

The launch of composite fiber filters truly means that high-precision filters can be applied to farms.

This material has low air resistance, good damage resistance, and moisture resistance that are unmatched by other materials.

At present, about 90% of pig farms around the world use filter elements made of this material for high-efficiency filtration. Composite fiber filter elements have stable performance, especially in areas with high humidity, ice, and snow.

Other aspects

In addition to the performance of the filter material itself, several other essential aspects of the air filter include whether it is fully filled with glue, whether it is produced in a sterile environment, whether the filter area is sufficient, whether the dirt-holding capacity is adequate, whether it is double-sided sealed, and whether it is double-layered packaging, etc.

Can I use a custom air filter on a swine farm?

Is it advisable to customize air filters of different sizes or varieties for swine farms? Based on my industry experience, I recommend something other than this.

When some pens are renovated or upgraded, customization methods will have to be adopted due to the limitations of the building structure.

However, I recommend that users use industry standard size or universal type filters as much as possible. The advantage of using standard-size filters is that users can reduce additional costs during future operation and maintenance.

Both sizes, 24″ x 24″ and 20″ x 24″, are common in the industry, and most standard-size air filters from different brands can be interchanged without modifying the building hardware.

The swine farm’s air filtration system is an all-weather epidemic prevention system in application and is also part of the fresh air supply and ventilation system.

This determines that the air filter supply chain needs to have the characteristics of rapid response and uninterrupted supply. Once customized sizes are adopted, users may face the potential risk of supply interruption due to various problems.

Common ventilation and filtration solutions for pig houses

Various climate types determine the ventilation types of swine farms in different regions.

Common ones include negative pressure ventilation and positive pressure ventilation.

Therefore, in addition to the air conditioning filtration system, there are three common ventilation filtration solutions used in actual swine farm production:

Negative pressure ventilation filtration: The air filter requires a large area, the frequency of air filter replacement is low, the energy consumption of the ventilation system is low, and the requirements for the building structure of the barn are high.

Positive pressure ventilation filtration: The air filter area required is small, the frequency of air filter replacement is high, the energy consumption of the ventilation system is high, and the requirements for the building structure of the barn are low.

Balanced ventilation or micro positive pressure ventilation: the air filter area required is medium, the frequency of air filter replacement is high, the energy consumption of the ventilation system is high, and the requirements for the building structure of the pen are low.

How to choose a Ventilation filtration solution in a swine farm?

Negative pressure ventilation design has good cooling capacity and economical energy consumption and is adopted by most users.

Because of the air tightness of negative pressure ventilation, when users consider using an air filtration system, they will first consider whether negative pressure ventilation is suitable for the air filtration system.

Many users have asked about which ventilation filtration solution is suitable. For this reason, I suggest that it depends on the degree of air cleanliness required and the area where the breeding farm is located. For example, in SPF animal farms, positive-pressure ventilation filtration is the preferred solution.

In the core group farm, multiple solutions are used to match different pens.

For areas and breeding species sensitive to heat emergencies, I suggest using negative pressure ventilation and filtration designs to ensure sound ventilation effects and low energy consumption to meet actual production needs.

Last summary

Air filters are an essential part of swine farm biosecurity. Choosing a rigorous filtration system and a matching ventilation and environmental control system can effectively prevent the spread of diseases and create a clean environment.