V-bank air filters have more dust-holding capacity than regular mini-pleat, cartridge, or box-style filters. They capture particles quite effectively and hold up well in tough applications, such as changes in air volume, fluctuating airflow patterns, and damp conditions.

The specially designed thermoplastic spacer ensures the same pleat spacing in V bank filters.

It ensures that the airflow passes through with minimum resistance while the design increases the filter media area, thus reducing energy consumption and saving operating costs.

Why did it call V bank?

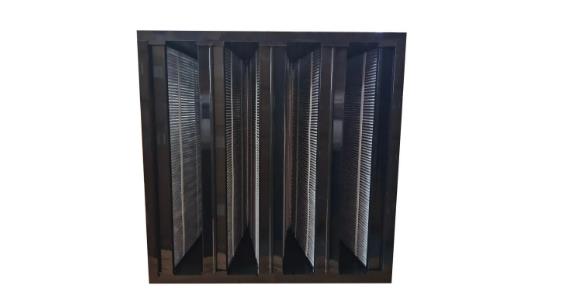

The V bank air filters are designed without a separator, forming a “V” or “W” type structure, and are made of low-resistance ultra-fine glass fiber filter paper.

It has a compact and reasonable structure, with a larger effective filtration area, long filter life, high efficiency, low-pressure drop, and can operate stably at high air velocities.

It is suitable for air filtration at the end of air supply and air conditioning equipment, at the negative pressure end of exhaust air purification systems, and ventilation ducts.

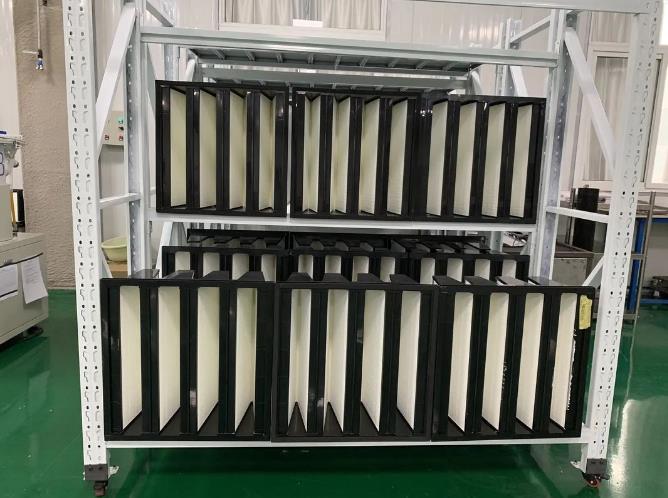

The V-filter is available in different V-numbers, such as 2V, 3V, 4V, 5V, etc. A V-filter unit provides a more substantial air supply effect.

Designed for high airflow with low resistance

The V bank filter has been specially developed for applications requiring high airflow at low resistance, with a filter media area 1-3 times larger than conventional models.

It is easier to achieve higher efficiency and higher dust capacity.

At the same air volume, the initial resistance is much lower than that of conventional filters, resulting in higher energy efficiency and lower operating costs.

The V bank filter media is made of ultra-fine fibers or sometimes synthetic fibers, waterproof, separated by a continuous melt glue, and arranged in a V-shape in a very tight ABS support frame.

The filter area is significantly increased in a limited space, resulting in a thinner, more robust filter with reduced fan energy consumption at a fixed pressure drop.

V bank air filters have excellent filtration efficiency for fine particles, mainly capturing airborne dust particles above 0.3um. The maximum air volume of the V BANK Hepa filter design can reach 4200m3/h.

It can replace the pocket filter in some applications.

VBANK filters are preferred as an alternative to pocket filters in many projects because they take up small space, their high filtration efficiency and dust-holding capacity, and the fact that they are replaced less frequently than the pocket filter.

Basic informtion of V bank filter

1. The V BANK filter is designed with a mini pleat, and the thermoplastic separator ensures the same pleat spacing and low resistance to airflow.

The same pleat spacing makes full use of the entire depth of the filter material and guarantees a higher dust capacity.

2. It has a high airflow and can use fewer filters for the same airflow than ordinary air filters, reducing costs reducing installation space, and saving installation time.

3. The V Bank air filters have a lightweight ABS plastic frame and low initial resistance.

This filter is particularly suitable for complex operating systems such as high air velocity systems, turbulence air volume systems, high humidity or corrosive environments, and other special requirements.

4. It has a temperature resistance of 80 degrees

5. It operates at 100% humidity

6. Filter efficiencies can be customized from F8 – H14

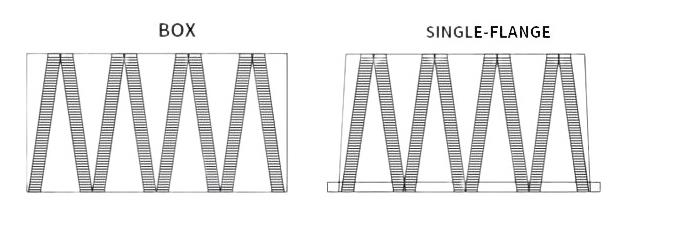

7. Available in ABS plastic, galvanized, or stainless steel frame with/without flang.

Features of V bank filter

1. The V Hepa Bank filter can achieve an airspeed of 2.5m/s (i.e., 500fpm) at an initial resistance of 250Pa.

2. The V bank filter has a longer life span, with twice the spread of the filter media than conventional filters, providing a longer service life.

3. The filtration efficiency increased, and reduced filtration speed due to the increased area of the filter media made it very easy to achieve 99.99%@0.3um.

4. Lower running costs, the initial resistance of a conventional filter is 1.3 times higher than the initial resistance of a V bank filter for the same air volume, which results in energy savings when using a V bank filter.

6. Low resistance, compact and reasonable V-filter structure, high efficiency, large filter area, resistance not higher than 250 Pa at rated air volume.

5. High airflow, V bank filters are suitable for central air conditioning and supply air ducts, with a rated airflow of up to 3600m3/h per standard size 610x610x292mm V filter at a surface air velocity of 2.7m/s.

V bank filter applications

It is used in air conditioning supply systems where a high level of cleanliness is required.

The V-filter can be installed in central air conditioning to protect the end Hepa/ULPA filters in a clean room or ducts for process air supply systems with special cleanliness requirements.

1. Used in commercial heating and ventilation air conditioning systems, such as office buildings, hospitals, shopping malls, stadiums, airports, and other prominent city buildings.

2. Used in ventilation, air conditioning systems, and terminal filtration of central air conditioning units.

3. Used in centralized ventilation systems for electronic, pharmaceutical, food, and semiconductor applications requiring high cleanliness.

The V Bank Hepa filter is suitable for use in research and production sectors with various processes requiring cleanliness below 100,000.

Due to its good bacterial filtration performance, this V filter is particularly suitable for the pharmaceutical industry, biological laboratories, hospital operating theatres, and food and cosmetics industries.

It also has a good effect on the air purification of offices and hotels. Therefore, the V bank air filters can be used as a final filter for the above occasions and guarantee the cleanliness requirements of class 100,000.

V Bank filter in Commercial ventilation systems

The factors affecting the ventilation of large commercial buildings are diverse.

It is necessary to thoroughly combine temperature, humidity, and environmental quality factors to analyze how the ventilation and air conditioning system is composed.

Comprehensive analysis of air conditioning in shops, public areas, and catering areas, and a good division of the different business areas, to ensure the accuracy of ventilation filtration.

Physical environment requirements for large commercial buildings

1. Temperature

As commercial buildings grow, the heat generated during the operation of the internal equipment is more significant.

In order to keep the safety of the interior of commercial buildings, ventilation and air conditioning need to be reasonably designed to provide adequate circulation of air within the building.

For this reason, it is essential to monitor the temperature of the exterior and interior of the building during the use of ventilation and air conditioning so that the temperature difference is within the optimum range.

The V Bank filter has high-temperature stability and filtration efficiency and works consistently within the target temperature range to ensure air quality.

2. Humidity

Large commercial buildings’ indoor air quality requirements can be effectively met when the humidity level in the environment is controlled between 50% and 60%.

Ventilation, air conditioning, and filtration ensure air circulation, and the V bank filter can operate under 100% humidity, helping to improve the overall air quality inside large commercial buildings.

3. Air quality

Polluting gases outside the building, including sulfur dioxide and nitrous oxide, are constantly monitored and studied.

In order to create a good ventilation environment in the building, the air conditioning ventilation system with air filters can filter the polluting gases in time.

The polluting gases inside large commercial buildings are mainly volatile organic gases, bacteria, odors, and smoke, so filters such as V bank activated carbon filters are configured for polluting gases in different areas. In this way, pollution is reduced, and air quality is improved.

Filtration methods to improve the indoor environment of commercial buildings

At present, air purification system projects in commercial buildings are divided into three main categories:

1. Single-unit air purifiers

2. Building ventilation purification systems.

3. Combine air conditioning units with air purification devices, filtration sections in the chassis, air ducts or air outlets, etc.

The technology includes physical filtration, electrostatic dust removal, ion purification, adsorption purification, photocatalyst, etc.

These are done through building renovation to improve indoor air quality and by improving the filtration capacity of the air conditioning system to remove dust from the ventilation process.

We can also use the following methods to enhance the ventilation filtration effect:

- The fan should be selected with sufficient full pressure to overcome the final resistance of the multi-stage filter.

- Try to use a variable frequency drive motor to adjust output power during operation to adapt to internal resistance changes and maintain constant air volume.

- Adjusting the air leakage rate of the air conditioning box, the sealing performance of the filter section frame, and the filter border.

- Control the design of indoor airflow and the number of air changes.

- Choose the right filter – not the higher efficiency is better.

- Maintenance work: cleaning duct sections and air conditioning boxes and regularly inspecting and replacing air filters.

Select V bank filters with different functions.

Large commercial building ventilation system focuses on improving the cleanliness of the building’s indoor air, and the process of ventilation requires using a total air ventilation system, mainly in the form of low-speed one-way ducts.

Choose the best filter in the pre-design stage of the ventilation system in order to enhance the design effect of ventilation, take advantage of the combined ventilation and air conditioning unit, and the airflow is mainly in the form of air supply from top and air return in low of the building.

In the ventilation design, we should choose filters with corresponding filtration functions and efficiency for different pollutants such as PM2.5, CO, volatile gases, smoke, etc.

V bank filters in the livestock industry

Due to the large area of animal farms, the large number of animals farmed, and the tight spaces, ventilation systems with high air volumes are often used to circulate the air inside the farm, remove germs and odors and reduce disease incidence.

Therefore, V Bank filters with high filtration efficiency and long service life for large air volumes are used in the livestock industry.

Why livestock farming needs ventilation and filtration systems?

Livestock farming is one of the components of agriculture and is one of the two pillars of agricultural production, along with farming.

Unlike family subsistence livestock farming, the main characteristics of livestock farming are that it is concentrated, large-scale, and profit-oriented, so epidemic prevention and safety are of the utmost importance.

Ensuring healthy farming of chickens, ducks, and pigs and supplying the market with hygienic meat is essential to all of us and is a matter of food safety.

In particular, infectious diseases in pigs caused by various viruses can result in the death of large numbers of pigs and thus bring about significant economic losses.

Therefore, good ventilation and filtration systems are needed to block the spread of bacteria and viruses and improve the air quality in animal farms.

Virus transmission through the air

Airborne transmission is a significant route of infection for many pathogens, including swine reproductive and respiratory syndrome virus, influenza virus and Mycoplasma pneumonia, avian influenza, swine fever, etc., which can be transmitted from one animal farm to another through the airborne route by means of atmospheric dust particles or other bioaerosols.

Air filtration systems can significantly cut off the airborne route of pathogens in animal populations. Still, the pathogen transmission route is not limited to airborne transmission, so integrated vaccination measures incorporating air filtration systems can be more effective and reliable in reducing farming risks.

Filtration and ventilation in animal farms

The air inlet of the animal farm is equipped with metal mesh to filter the leaves and mosquitoes in the air first to extend the air filter’s life.

The roof ceiling and wet curtain air inlets are equipped with middle and Hepa air filters, through which the air enters the farm, filtering out dust and impurities while blocking viruses.

Double doors are placed at all entrances to the farm, allowing negative pressure ventilation to reduce the risk of viruses being introduced via the air, and air return prevention devices are fitted outside the exhaust fans.

V bank filter to protect the animal from disease in livestock

V bank pleated air filters not only filter out biological aerosols but also filter out pathogenic microorganisms, significantly reducing the spread of disease.

1. Moisture, humidity, and corrosion resistance for standard filtration in all environments.

2. Using composite chemical fiber melt-blown material or ultra-fine glass fiber allows for the filtration of common viruses.

3. Used with a pre-filter to remove particles, dust, and germs in multiple ways.