The filter material is the core component of the Hepa filter. There are two primary HEPA filter materials: glass fiber and synthetic fiber.

Glass fiber has a wide range of applications in hepa filter materials, especially in industrial filtration. Glass fiber has been the preferred filter material for HEPA filters.

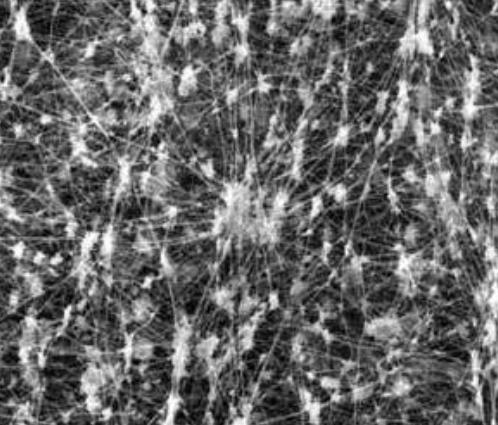

The chemical fiber can be loaded with static electricity to obtain higher filtration efficiency to remove airborne particles without causing an increase in resistance. Therefore, there is a vast market for electrostatically charged chemical fibers for high-efficiency particulate air filters.

What is a HEPA filter made of?

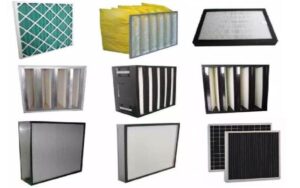

Hepa filters are usually made of housing, filter material, adhesive, protective fence, and sealing strips.

Since there are many shapes and structures of HEPA air filters and application scenarios, the selection and processing of housing and protective fence materials are also very varied.

But the critical material of the HEPA air filter is still the filter material, which determines the final performance of the HEPA air filter.

Why choose fiber-based filter materials for HEPA filters?

1. HEPA filter materials need to meet three basic requirements.

- Good filtration performance (high filtration efficiency, high filtration precision, low filtration resistance)

- Good physical and chemical properties (high fracture strength, chemical corrosion resistance, high-temperature resistance, aging resistance, etc.)

- Stable product quality (good dimensional stability and wear resistance).

Fiber-based filtration materials can perfectly meet these requirements.

2. The fiber filter material has a large specific surface area and appropriate internal space.

It can trap and adsorb airborne particles and airborne contaminants and separate them from the air. Fiber filtration material is one of the rapidly developing filtration materials.

3. The filtration mechanisms of fiber filter materials include five main categories: direct interception, inertial collision, gravitational deposition, Brownian motion effect, and electrostatic adsorption. These are also how HEPA filters work.

In practical filtration, several filtration mechanisms usually work in succession.

- Solid particles with larger diameters are captured directly.

- Particles with higher momentum are intercepted due to inertial collisions with the material.

- The fibers capture particles of greater mass due to their greater gravity.

- Smaller particles are deposited on the fibers due to the Brownian motion effect.

- Due to the electrostatic effect, charged and small particles are adsorbed by charged fibers.

Therefore, the fiber filter material is currently used for air filters, including HEPA filters.

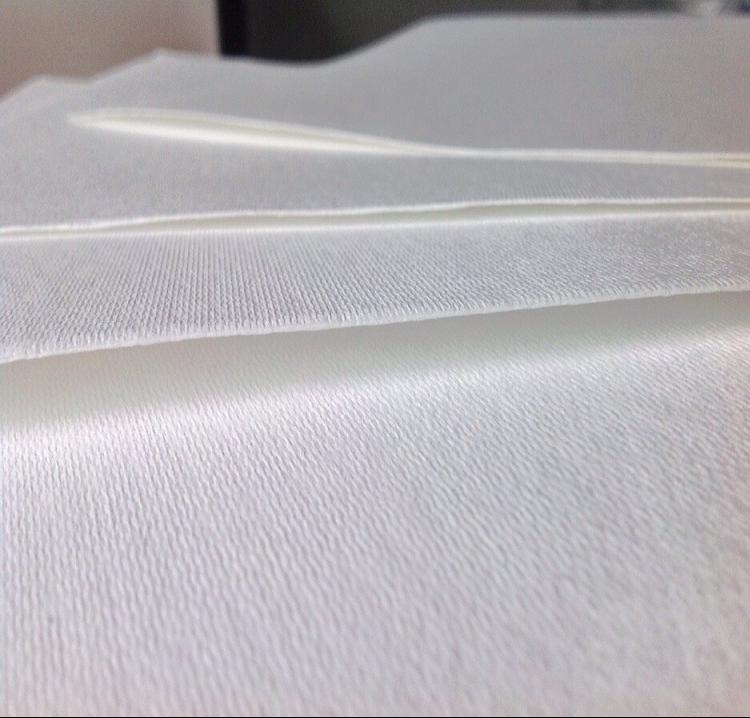

High-efficiency filter paper/sheet

The filter material made of glass fiber or chemical fiber looks like paper, so people also call them glass fiber filter paper or chemical fiber filter paper.

These filter materials are made according to different filtration efficiencies, such as H13 and H14 HEPA filter paper.

Sometimes, by adding the word high efficiency in front, it becomes high-efficiency glass or chemical fiber paper.

People also called them high-efficiency glass fiber sheets or chemical fiber sheets.

Glass fiber filter paper

Glass fiber filter media is also known as fiberglass filter paper. Glass fiber is the most commonly used material for HEPA filters, with a filtration efficiency of 99.9% to 99.99997% and other grades.

It can filter tiny particles and other airborne contaminants with a particle size of 0.1-0.3 microns or more.

Glass fiber’s biggest weakness is that it contains boron (B2O3) up to 10.7%.

Boron can react with hydrofluoric acid and is easy to generate silicon tetrafluoride.

So the filter material becomes broken, forming secondary pollution.

History

In October 1940, the application of glass fiber filter material in the air filtration industry was patented in the United States. In the 1960s, HEPA filters were introduced.

In the 1970s, the micro glass fiber filter paper was used as the primary material of HEPA filters, and air filtration technology officially entered a high-speed development stage.

Short-cut glass fiber and glass cotton

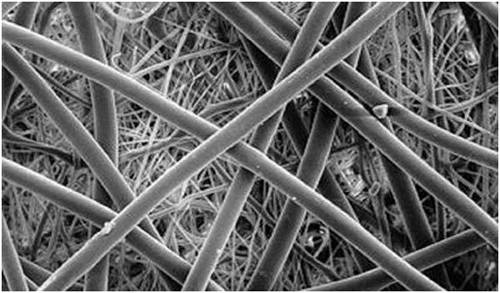

Glass fiber is mainly divided into short-cut glass fiber and glass cotton.

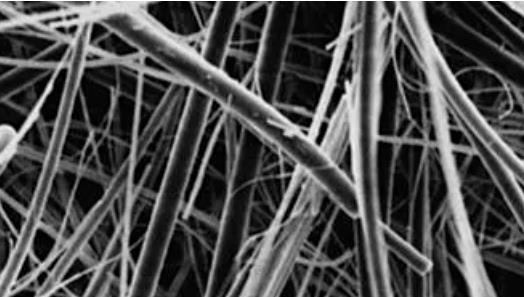

Glass fiber is molten by placing glass balls at a temperature of about 1500°C and then processed into a fibrous material using high-pressure meltblown or drawn.

The fibers obtained by drawing are of uniform diameter and are cut to the desired length to get the so-called short-cut glass fibers.

The melt-blown fibers are finer in diameter and form a cotton-like glass fiber, usually called glass cotton, with a specific fiber diameter and length distribution.

Composition and processing properties of glass fibers

The main glass fiber components are SiO2, Al2O3, calcium oxide, magnesium oxide, sodium oxide, etc., of which SiO2 accounts for 53-70%.

These oxides will show different acidity and alkalinity in water, with SiO2 representing the weak acid component and calcium oxide representing the vital base component. Thus the glass fiber surface has an ample weak acid point and a lower concentration of solid base point.

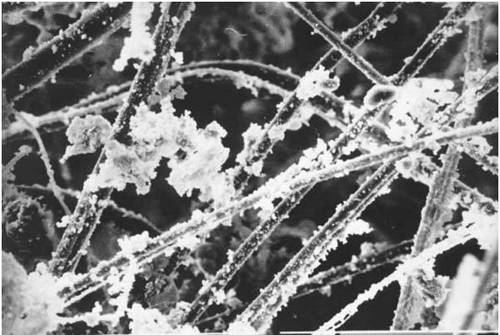

When glass fibers are in the water, these oxides cause the fiber surfaces to be oppositely charged, causing the fibers to attract each other and flocculate into clumps.

Whether the glass fiber can be more uniformly dispersed in the dispersion medium, thus promoting the realization of good interweaving between the fibers, is an essential factor affecting the filter performance of glass fiber filter paper.

The dispersion of glass fibers in water can be improved by lowering the pH of the slurry, adding surfactants, and increasing the viscosity.

The processing method of glass fiber filter material

Glass fiber paper is manufactured by the wet papermaking method by adding corresponding chemical reagents to disperse glass fibers in water to form a suspension uniformly and then filtering the water on a forming screen to get glass fiber paper.

The fine diameter of glass fibers enables high filtration precision to be achieved.

At the same time, the glass fiber modulus is high and relatively stiff, making the fiber diameter very small but not easy to pool, and the stacking density is relatively low. Thus the filtration resistance is also low.

The high efficiency and low resistance performance are why glass fiber filter paper dominates the market.

Application of glass fiber filter material

Ultra-fine glass fiber melt-blown filter media has fine fibers (0.5-5µm diameter), a large number and fluffy structure, high efficiency, low resistance, and long life compared with similar products. It can trap the smallest particles and has a higher filter efficiency rating.

Therefore, glass fiber filter media is the material of choice for HEPA filters in industrial or clean room ventilation and air conditioning systems.

It also has many applications in commercial filtration.

High-efficiency synthetic fiber filter material

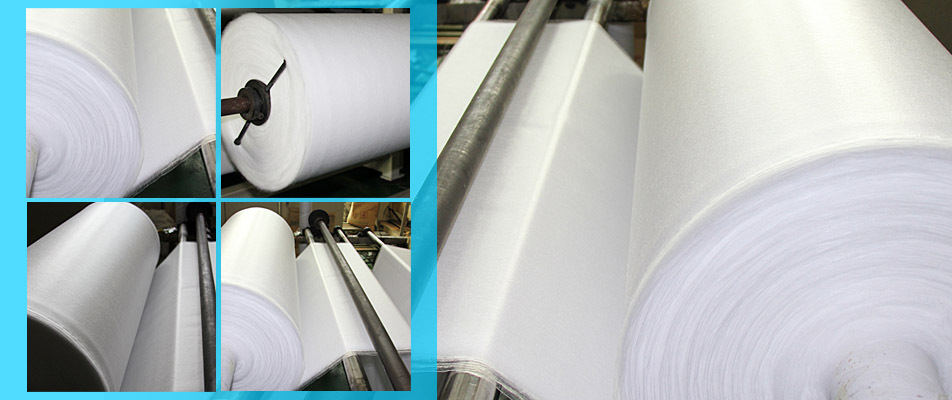

Chemical fiber nonwoven filter media is commonly known as nonwoven filter media.

Melt-blown, hot melt, spun-bond, needle punching, hydro entanglement, and other processes make it.

The advantages of chemical fiber filter paper are high-quality stability, large dust capacity, good moisture resistance, long service life, durable.

Disadvantages: cannot reach higher filter efficiency rating.

Chemical fiber high-efficiency filter paper is mainly used for filtration of commercial or residential settings.

Chemical fiber filter materials are used for indoor air purification to remove pet dander, human hair, mold, and allergens.

The fibers used in these indoor filtration materials are mainly synthetic fibers, such as polypropylene (PP) fibers, polyester (PET) fibers, and homopolymerized polypropylene (Pan) fibers.

The pre-filter is mainly made of glass fiber, PP, pet, metal mesh, etc., which can filter dust of 5.0µm in diameter. The intermediate air filter can reduce dust particles above 1.0μm in diameter.

Research shows that the efficiency of some high-efficiency chemical fiber filter media to filter dust of 0.3um in diameter can reach 99.99%.

Two different chemical fibers can be compounded.

Chemical fiber filter media has the advantages of simple structure, uniform pore size distribution, excellent filtration performance, and high yield.

Two or more kinds of chemical fibers can be superimposed to advantage with high strength and good filtration effectiveness.

In different environments, different processes can be used to produce chemical fiber filter materials, such as various forms of woven tissue (plain, twill, and satin), different weaving methods (flat and circular), and different ways of nonwoven reinforcement (needling and hydroentanglement).

Types of chemical fiber high-efficiency filter paper

PP (polypropylene) HEPA filter material

PP high-efficiency filter paper is made of polypropylene by a unique hot melt process.

PP filter material is acid and alkali-resistant, and corrosion-resistant.

It has a high melting point, stable performance, low resistance, and high efficiency and is non-toxic and odor-free.

PP high-efficiency filter paper is water resistant and can withstand temperatures up to 120℃.

It is ideal for home air purifiers, car, and HVAC system filtration.

PET high-efficiency filter material

PET HEPA filter material is made of polyester material through a melt-blown process, with high hardness, stable performance, corrosion resistance, and good stiffness.

However, the single filtration of PET filter paper is relatively low, generally only H10-H11 level (90% to 99.5% filtration efficiency).

It is commonly used in household appliances like sweepers or cleaning machines that do not need high filtration efficiency.

PP and PET composite HEPA filter material

Simply put, PP+PET hepa composite filter material is a layer of melt-blown PP with a layer of melt-blown PET as support material.

In this way, it has the advantages of both PP and PET. It is easy to shape, can guarantee filtration precision, low air resistance, high dust capacity, and good rigidity, and ensure the high precision filtration effect.

It is the best chemical fiber filter paper, and currently, on the market, many famous air cleaners and air purifier brands choose this filter material for their HEPA filters.

Pre-filter with activated carbon filters and HEPA filters in air purifiers can remove odors, pollen, bacteria, smoke, and viruses to improve air quality.

PTFE HEPA filter material

Poly tetra fluoroethylene, abbreviated as PTFE.

PTFE high-efficiency filter paper is obtained by heat laminating high-efficiency PTFE microporous film with chemical fiber filter paper. It can achieve H10-H14 efficiency.

Which has the advantages of high filtration efficiency, large dust capacity, low resistance, and can be repeatedly cleaned and used.

It is widely used in industries’ ventilation and air conditioning systems of air purification filtration.

Glass fiber HEPA filter paper vs. chemical fiber HEPA filter paper

Glass fiber high-efficiency filter paper has been previously used in the nuclear industry.

Compared with chemical fibers, glass fiber is characterized by high-temperature resistance, high dust-holding capacity, good stability, durability, and long life.

Its most important advantage, however, is that it can guarantee a high enough filtration efficiency in a single air pass. Until today, the highest efficiency of U15 ~ U17 filters is still glass fiber-based.

However, improving the filtration effect also increases air resistance, usually above 200Pa, and can only be relieved by increasing the fan power to ease the lack of airflow.

In contrast, chemical fiber high-efficiency filter paper is widely used in commercial and household filtration due to its mild nature, easy processing, and low air resistance, which is an efficient way to remove smoke, pollen, and mold from the air.

What are the influencing factors of HEPA filter material?

Many factors affect the efficiency of high-efficiency filter paper, the main ones being particle diameter, fiber thickness, filtration speed, etc.

Influence of particle properties

When filtering polydisperse particles, theoretical analysis and measurement results show that the total filtration efficiency tends to decrease and increase as the particle diameter changes from small to large.

This result is because various trapping mechanisms affect different particle sizes.

Smaller particles are deposited due to diffusion, while larger particles are trapped under the action of interception and inertia.

When the particle size is from small to large, the diffusion effect gradually decreases, and the inertia and interception efficiency gradually increases, which leads to the total trapping efficiency in the small particle size range tending to be weaker.

Even if the particle size is the same, particles in different phases affect the filtration efficiency, and solid particle measurement can lead to high filter efficiency.

Influence of fiber thickness

The filtration efficiency decreases with increasing fiber diameter when all other parameters are constant and only the fiber diameter varies.

This decrease is because as the diameter of the fiber increases, the interception coefficient of the interception effect decreases accordingly, resulting in a decrease in the capture efficiency of the two mechanisms involved, thus causing a reduction in the total filtration efficiency.

This is why the fibers in high-efficiency filter paper are much finer than those in medium-efficiency filter paper. Of course, the finer the fiber, the higher the resistance.

In addition, as the fiber diameter increases, the interception coefficient decreases, the inertia effect is weakened, and the most penetrating particle size also gradually becomes larger. The extreme point of the efficiency curve then moves to the right.

Influence of filtration speed

When the filtration speed increases, the diffusion effect decreases, the inertia effect increases, and the interception efficiency increases, so the total efficiency decreases first and then increases.

At the same time, as the filtration speed decreases, the filtration efficiency of the filter paper increases significantly. When the filtration speed is reduced by a factor of 1, the filtration efficiency rises by order of magnitude.

This efficiency increase is because lowering the filtration speed makes the particles pass through the filter paper for a more extended time, thus increasing the chance of the particles being captured, and thus the efficiency increases significantly.