Maintaining exceptional air quality is vital for creating clean and healthy environments, particularly in medical and industrial settings. True High-Efficiency Particulate Air (HEPA) filters are indispensable tools that effectively eliminate airborne contaminants. However, the market is rife with filters that claim to be “HEPA-like” or “HEPA-style,” which do not meet the stringent standards of certified HEPA filters. This article explores the significance of using genuine HEPA filters, the differences between certified and non-certified filters, and how to select the appropriate HEPA filter for your facility.

What Is a True HEPA Filter?

A true HEPA filter is a specialized mechanical air filter designed to trap at least 99.97% of airborne particles as small as 0.3 microns. Composed of densely interwoven glass and synthetic fibers, these filters capture microscopic particles through mechanisms like interception, impaction, and diffusion.

HEPA Filter Standards and Certifications

The United States Department of Energy (DOE) sets rigorous standards for HEPA filters. To earn certification, a filter must demonstrate its efficiency in removing particles at the specified micron level. The Minimum Efficiency Reporting Value (MERV) rating, established by the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE), further categorizes filters based on their performance, with higher ratings indicating superior efficiency.

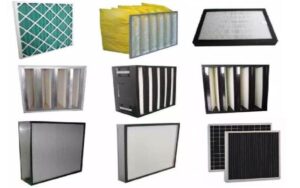

Types of HEPA Filters

Understanding the different types of HEPA filters is crucial for selecting the right one for your needs.

1. True HEPA Filters

- Definition: Meet DOE standards by capturing 99.97% of particles at 0.3 microns.

- Applications: Ideal for environments requiring high air purity, such as hospitals and cleanrooms.

2. H13 and H14 Medical-Grade HEPA Filters

- H13 Filters: Capture 99.95% of particles down to 0.2 microns.

- H14 Filters: Capture 99.995% of particles at the most penetrating particle size.

- Usage: Essential in medical settings with vulnerable populations.

3. “HEPA-like” or “HEPA-style” Filters

- Definition: Filters that claim HEPA-level performance without meeting official standards.

- Limitations: Lack certification and rigorous testing, resulting in lower efficiency.

Differences Between True HEPA and HEPA-like Filters

Distinguishing between certified HEPA filters and their imitations is vital for ensuring air quality.

Certification and Testing

- True HEPA Filters: Undergo stringent testing to meet DOE standards.

- HEPA-like Filters: Not subjected to official certification processes.

Filtration Efficiency

- True HEPA Filters: Remove 99.97% of particles at 0.3 microns.

- HEPA-like Filters: Efficiency is unverified and generally lower.

The Role of HEPA Filters in Medical Facilities

HEPA filters are critical components in healthcare environments for controlling airborne contaminants.

Applications in Healthcare Settings

- Operating Rooms: Prevent surgical site infections by filtering airborne pathogens.

- Intensive Care Units: Protect immunocompromised patients from contaminants.

- Laboratories: Maintain sterile conditions to prevent cross-contamination.

MERV Ratings Required in Medical Facilities

Different areas require specific MERV ratings to ensure adequate air filtration.

| Facility Area | Minimum MERV Rating |

|---|---|

| Operating Rooms | MERV 14 |

| Intensive Care Units | MERV 14 |

| Laboratories | MERV 13 |

| Procedure Rooms | MERV 13 |

| Nursing Facilities | MERV 13 |

| Recovery Spaces | MERV 14 |

Selecting the Appropriate HEPA Filter for Your Facility

Choosing the right HEPA filter involves assessing your facility’s specific air quality needs.

Assessing Air Quality Requirements

- Identify Contaminants: Determine the types of particles prevalent in your environment.

- Vulnerable Populations: Consider the health of individuals occupying the space.

Evaluating Filter Specifications

- Efficiency Ratings: Look for filters with appropriate MERV and HEPA ratings.

- Certification: Ensure the filter is officially certified as a true HEPA filter.

How HEPA Filters Impact Different Environments

HEPA filters enhance air quality across various settings beyond healthcare.

Industrial Applications

- Manufacturing Plants: Protect equipment and products from dust and particulates.

- Pharmaceutical Production: Maintain sterile environments to comply with regulations.

Commercial and Residential Use

- Office Buildings: Improve indoor air quality for employee well-being.

- Homes: Alleviate allergies by removing common airborne irritants.

The Benefits of Using Approved HEPA Filters

Investing in certified HEPA filters offers numerous advantages.

Enhanced Air Purity

- Efficient Particle Removal: Traps microscopic particles, reducing health risks.

- Allergen Reduction: Minimizes exposure to pollen, dust mites, and mold spores.

Equipment Protection

- Extended Lifespan: Prevents buildup in HVAC systems, reducing maintenance.

- Regulatory Compliance: Meets industry standards for air quality.

The Importance of Avoiding Non-Certified Filters

Using non-certified filters can have serious consequences.

Health Risks

- Inadequate Filtration: Allows harmful particles to circulate, endangering occupants.

- False Sense of Security: Misleads users into believing the air is properly filtered.

Financial Implications

- Operational Downtime: Contamination can lead to costly shutdowns.

- Legal Penalties: Non-compliance with air quality regulations can result in fines.

Conclusion

Understanding the difference between true HEPA filters and non-certified alternatives is important for maintaining optimal air quality. Certified HEPA filters are critical for protecting health, ensuring regulatory compliance, and safeguarding equipment across various industries. When selecting a HEPA filter, prioritize certified options to provide the highest level of air purification for your facility.