Whatever your needs – shape, material, color, efficiency, or application – we’ve got you covered.

We can custom and OEM air filters for various applications and have supplied more than 200 kinds of air filters in different designs. Especially in OEM air purifier filters and vacuum cleaner filters, we have accomplished more than 80 projects. Our strong design and R&D capabilities will help your project come to fruition quickly.

Home HVAC Systems

Primary filtration, activated carbon, high efficiency filtration

Various shapes of high-efficiency filtration components

Various shapes of high-efficiency filtration components

Filters hair, dust, and allergens

Removal of smoke, dust, mold and other pollution in the car

Filtering of ash, unburned particles and dust

Filter PM2.5, pollen, mold, VOC and dust

When you’re customizing a filter, you have to know how big it is. Here’s how to measure your filter:

If your filter is square, measure all four sides to make sure they’re the same. If your filter is round, measure the distance across the middle in a few different places to make sure it’s the same.

If your filter is round, make sure it’s a perfect circle and not a little bit squished. If it’s not a perfect circle, the measurement across the middle might not be right.

In addition to length and width, make sure you measure the depth or thickness of the filter. This can have a big impact on how well the filter works.

Write Everything Down as You Go:

As soon as you take a measurement, write it down so you don’t forget. Also, make sure you label which measurement goes with which dimension.

Angle Precision: When you measure beveled edges, it’s important to know the angle of the bevel. This angle determines how the filter will fit into its slot or frame. If you need to, use an angle measuring tool.

Measure Both Surfaces: When you have a bevel cut, remember that you have a longer surface (the outside) and a shorter surface (the inside) because of the angle. You need to measure both surfaces to get the right dimensions.

Depth Consistency: Just like with regular filters, the depth or thickness of the filter is important. Make sure you have consistent depth measurements all the way across the filter, especially in the beveled areas.

Check the Corners: When you’re dealing with square bevel cuts, sometimes the corners can be different from the rest of the edges. Double-check to make sure they’re consistent and that the beveling is the same or not.

Document Carefully: Because bevel cuts are more complicated, write down each measurement clearly and say which one is the inside measurement and which one is the outside measurement. It’s also helpful to make a quick drawing so you can look at it later.

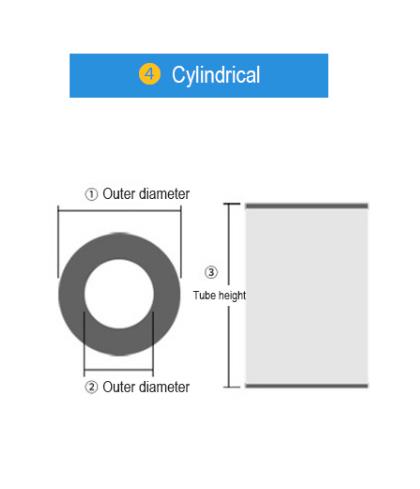

Diameter First: Start by measuring the diameter of the cylindrical filter. The best way to do this is to measure straight across the middle of the circle. Make sure the measuring tape is pulled tight so you get an accurate measurement.

Measure the Height: With cylindrical filters, the “height” is the distance from the bottom of the cylinder to the top. Put your tape measure or ruler at the bottom and measure up to the top edge.

Inner Diameter: The inside diameter is also important for some cylindrical filters. You can measure across the opening on the inside, especially if the filter has a hollow or core on the inside.

Check for Tapering: Some cylindrical filters may be slightly wider at the top or bottom. If that’s the case, measure the diameters at both ends to make sure you get the right size.

Be Aware of Caps or Gaskets: If your cylindrical filter has an end cap, gasket, or any other added parts, keep this in mind when measuring. The cap or gasket can affect how the filter fits and where it ends up, so be sure to mention these details when you order or talk to the manufacturer.

Peace of Mind Performance: People can count on your filters to work right every time because we make sure they’re good.

Work with professional custom filter people in China. We’ll do whatever you want and use the latest technology to make it happen.

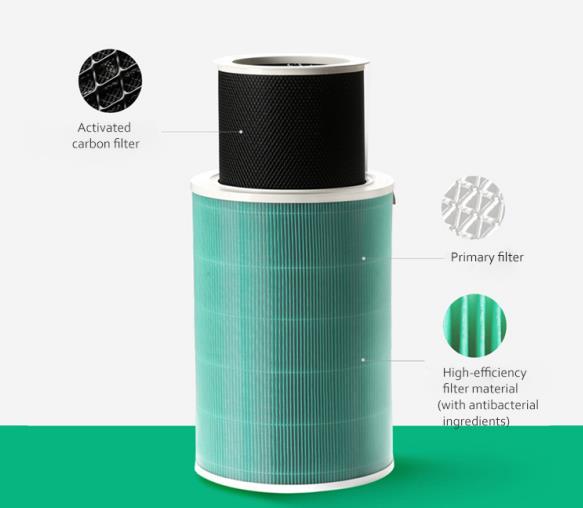

Air purifier filters are the most important part of any air cleaner. We make filters that catch lots of stuff in the air, like pollen and pet hair, and even tiny things like germs. Our filters are really good and get rid of more than 99.97% of the pollutants in the air. They make the air in your house, office, or factory better. We make filters that are new and different and work really well. We make filters that are new and tough and work great, so you get the best air possible.

HEPA filtration is generally more than the H12 level. The higher the level of filtration effect is better. H12 filtration effect on ≥ 0.3μm particles can reach 99.5%, H13 filtration effect can get 99.97%. The current market air purifier generally uses H12, 13 filters. If you use the H14 filter with higher filtration accuracy, the resistance will increase, which will cause the ventilation of the cleaner to decrease. If you want to maintain the airflow, you can only increase the speed to increase the power, which is more power-consuming and noisy.

Adding a layer of an activated carbon filter can adsorb and remove odor, VOC, and other harmful substances. A commonly used activated carbon filter is a honeycomb plate infused carbon. Only high hardness, high strength, and microporous activated carbon can be used as air-purifying activated carbon. The activated carbon filter will be saturated in about six months, and a new one needs to be replaced.

Before the HEPA, activated carbon filter, a primary filter will be placed, mainly to filter some large particles and dust, to reduce the consumption of HEPA filter. Considering the recyclability and low cost, most primary filters are a layer of washable filters, such as nylon, PP, or metal filters.

In order not to let the tiny bits of dust that are sucked into the vacuum cleaner escape to the outside, the vacuum cleaner is equipped with various filters. Generally, there are at least 2-3 filters, which prevent microscopic dust from damaging the motor and also prevent the soiling of the room air. The housing material is usually PP, and the filter material is synthetic fiber.

The role of the sweeper filter is similar to that of the vacuum cleaner filter, which can filter the hair, dust, particles, and food scraps in the cleaning process and protect the indoor air and the motor of the sweeper and other components.

A dehumidifier filter is a part of a dehumidifier that takes dust, particles, and sometimes allergies out of the air when it goes through the dehumidifier. It makes the air in your house better by catching bad stuff before it comes back out.

How much custom filters cost depends on how hard they are to make, what they’re made of, and how many you get. They might cost more than regular filters because we make them just for you, but they work better and last longer. You have to think about what you get and what you pay to decide what’s best for you.

When you order a custom filter, you have to give us the right sizes and information. It helps if you tell us what kind of equipment you have and what you need. Sometimes, we might even make you a sample filter to make sure it fits before they make a bunch.

It depends on what the warranty says. Some brands say you have to use their filters to keep the warranty. Before you get a custom filter, you have to check to see what the warranty says. But lots of times, custom filters are made to be just as good as the regular ones, so you don’t have to worry about how they work.

For sure! Custom filters are made to fit what you need, and if you get them from the right people, they can be just as good as the regular filters. You have to find a good filter person who knows what you need and makes filters that work the right way.

Let us know your project and work together.