Top-Notch Efficiency: Do you need good filters? Our cleanroom HEPA filters are guaranteed to perform, capturing at least 99.97% of 0.3 micrometers particles. We’re here to help you keep your cleanroom clean.

Quality Design & Built: Our filters don’t just work great, they last a long time. They’re made to make the air move evenly and they’re made to last in tough cleanroom conditions. You can trust our filters to work right.

Cleanroom HEPA filters are HEPA filters made just for cleanrooms. They usually use glass fiber filter material and mini pleat construction to get more filter area and less resistance. They take out at least 99.97% of particles 0.3 microns in size. These filters meet the tough air requirements of cleanrooms.

The filter media in a cleanroom HEPA filter is made of a lot of fibers packed close together. The fibers are usually made of glass. The fibers make a lot of different paths for the air to go through. The air goes through the filter in different ways and catches the particles. The particles hit the fibers, get stuck in the fibers, or get stuck because of the way the air moves.

So, why do you need these filters in your cleanroom?

Great Air Quality: Cleanrooms need to be really clean to work right. It doesn’t matter if you work in electronics, pharmaceuticals, or biotech. If you get particles in your cleanroom, it can mess up your products. With a cleanroom HEPA filter, you keep the air in your place clean, and you keep the stuff out that can mess up your work.

Meeting Standards: Cleanrooms have to follow a lot of rules and standards, like ISO 14644 and EU GMP. When you use HEPA filters, you follow these rules. You can show your cleanroom is clean enough.

Protecting People and Prodcuts: Cleanroom HEPA filters keep your things safe and keep your people safe. They keep out bad particles all the time, so the air is clean for your people to work there.

HEPA filters and ULPA filters are both used in cleanrooms. ULPA filters are even better at taking out particles.

Here is a simple way to classify them:

HEPA H13: This class of filter takes out 99.97% of particles 0.3 microns in size. They use these filters in pharmaceutical, hospital, and car cleanrooms.

HEPA H14: This class of filter takes out 99.997% of particles 0.3 microns in size. They use these filters in pharmaceutical, hospital, and microelectronics cleanrooms. They use these filters when you have to have a high level of clean air.

ULPA U15 to U17: These classes of filters take out more than 99.9995% of particles 0.1-0.2 microns in size. They use these filters in the most important cleanrooms, like semiconductor and chip cleanrooms.

| Dimention (W*H*D)mm | Filter class | Efficiency(%) EN1822 | Rated air flow (m3/h) | Initial resistance =<(Pa) | Rated air flow (m3/h) | Initial resistance =<(Pa) | Rated air flow (m3/h) | Initial resistance =<(Pa) |

|---|---|---|---|---|---|---|---|---|

| 320x320x69 | H13 | >=99.97%@0.3um | 166 | 115 | 276 | 195 | 332 | 235 |

| 484x484x69 | H13 | >=99.97%@0.3um | 379 | 115 | 632 | 195 | 759 | 235 |

| 570x570x69 | H13 | >=99.97%@0.3um | 526 | 115 | 877 | 195 | 1053 | 235 |

| 600x600x69 | H13 | >=99.97%@0.3um | 583 | 115 | 972 | 195 | 1166 | 235 |

| 915x610x69 | H13 | >=99.97%@0.3um | 904 | 115 | 1507 | 195 | 1808 | 235 |

| 948x484x69 | H13 | >=99.97%@0.3um | 759 | 115 | 1265 | 195 | 1518 | 235 |

| 1170x570x69 | H13 | >=99.97%@0.3um | 1080 | 115 | 1801 | 195 | 2161 | 235 |

| 1170x1170x69 | H13 | >=99.97%@0.3um | 2218 | 115 | 3696 | 195 | 4435 | 235 |

| 1220x610x69 | H13 | >=99.97%@0.3um | 1206 | 115 | 2009 | 195 | 2411 | 235 |

| 320x320x80 | H13 | >=99.97%@0.3um | 166 | 95 | 276 | 160 | 332 | 200 |

| 484x484x80 | H13 | >=99.97%@0.3um | 379 | 95 | 632 | 160 | 759 | 200 |

| 570x570x80 | H13 | >=99.97%@0.3um | 526 | 95 | 877 | 160 | 1053 | 200 |

| 600x600x80 | H13 | >=99.97%@0.3um | 583 | 95 | 972 | 160 | 1166 | 200 |

| 915x610x80 | H13 | >=99.97%@0.3um | 904 | 95 | 1507 | 160 | 1808 | 200 |

| 948x484x80 | H13 | >=99.97%@0.3um | 759 | 95 | 1265 | 160 | 1518 | 200 |

| 1170x570x80 | H13 | >=99.97%@0.3um | 1080 | 95 | 1801 | 160 | 2161 | 200 |

| 1170x1170x80 | H13 | >=99.97%@0.3um | 2218 | 95 | 3696 | 160 | 4435 | 200 |

| 1220x610x80 | H13 | >=99.97%@0.3um | 1206 | 95 | 2009 | 160 | 2411 | 200 |

| 320x320x93 | H13 | >=99.97%@0.3um | 166 | 85 | 276 | 145 | 332 | 190 |

| 484x484x93 | H13 | >=99.97%@0.3um | 379 | 85 | 632 | 145 | 759 | 190 |

| 570x570x93 | H13 | >=99.97%@0.3um | 526 | 85 | 877 | 145 | 1053 | 190 |

| 600x600x93 | H13 | >=99.97%@0.3um | 583 | 85 | 972 | 145 | 1166 | 190 |

| 915x610x93 | H13 | >=99.97%@0.3um | 904 | 85 | 1507 | 145 | 1808 | 190 |

| 948x484x93 | H13 | >=99.97%@0.3um | 759 | 85 | 1265 | 145 | 1518 | 190 |

| 1170x570x93 | H13 | >=99.97%@0.3um | 1080 | 85 | 1801 | 145 | 2161 | 190 |

| 1170x1170x93 | H13 | >=99.97%@0.3um | 2218 | 85 | 3696 | 145 | 4435 | 190 |

| 1220x610x93 | H13 | >=99.97%@0.3um | 1206 | 85 | 2009 | 145 | 2411 | 190 |

| 320x320x110 | H13 | >=99.97%@0.3um | 166 | 50 | 276 | 85 | 332 | 115 |

| 484x484x110 | H13 | >=99.97%@0.3um | 379 | 50 | 632 | 85 | 759 | 115 |

| 570x570x110 | H13 | >=99.97%@0.3um | 526 | 50 | 877 | 85 | 1053 | 115 |

| 600x600x110 | H13 | >=99.97%@0.3um | 583 | 50 | 972 | 85 | 1166 | 115 |

| 915x610x110 | H13 | >=99.97%@0.3um | 904 | 50 | 1507 | 85 | 1808 | 115 |

| 948x484x110 | H13 | >=99.97%@0.3um | 759 | 50 | 1265 | 85 | 1518 | 115 |

| 1170x570x110 | H13 | >=99.97%@0.3um | 1080 | 50 | 1801 | 85 | 2161 | 115 |

| 1170x1170x110 | H13 | >=99.97%@0.3um | 2218 | 50 | 3696 | 85 | 4435 | 115 |

| 1220x610x110 | H13 | >=99.97%@0.3um | 1206 | 50 | 2009 | 85 | 2411 | 115 |

| Dimention (W*H*D)mm | Filter class | Efficiency(%) EN1822 | Rated air flow (m3/h) | Initial resistance =<(Pa) | Rated air flow (m3/h) | Initial resistance =<(Pa) | Rated air flow (m3/h) | Initial resistance =<(Pa) |

|---|---|---|---|---|---|---|---|---|

| 320x320x69 | H14 | >=99.997%@0.3um | 166 | 140 | 276 | 235 | / | / |

| 484x484x69 | H14 | >=99.997%@0.3um | 379 | 140 | 632 | 235 | / | / |

| 570x570x69 | H14 | >=99.997%@0.3um | 526 | 140 | 877 | 235 | / | / |

| 600x600x69 | H14 | >=99.997%@0.3um | 583 | 140 | 972 | 235 | / | / |

| 915x610x69 | H14 | >=99.997%@0.3um | 904 | 140 | 1507 | 235 | / | / |

| 948x484x69 | H14 | >=99.997%@0.3um | 759 | 140 | 1265 | 235 | / | / |

| 1170x570x69 | H14 | >=99.997%@0.3um | 1080 | 140 | 1801 | 235 | / | / |

| 1170x1170x69 | H14 | >=99.997%@0.3um | 2218 | 140 | 3696 | 235 | / | / |

| 1220x610x69 | H14 | >=99.997%@0.3um | 1206 | 140 | 2009 | 235 | / | / |

| 320x320x80 | H14 | >=99.997%@0.3um | 166 | 120 | 276 | 195 | 332 | 245 |

| 484x484x80 | H14 | >=99.997%@0.3um | 379 | 120 | 632 | 195 | 759 | 245 |

| 570x570x80 | H14 | >=99.997%@0.3um | 526 | 120 | 877 | 195 | 1053 | 245 |

| 600x600x80 | H14 | >=99.997%@0.3um | 583 | 120 | 972 | 195 | 1166 | 245 |

| 915x610x80 | H14 | >=99.997%@0.3um | 904 | 120 | 1507 | 195 | 1808 | 245 |

| 948x484x80 | H14 | >=99.997%@0.3um | 759 | 120 | 1265 | 195 | 1518 | 245 |

| 1170x570x80 | H14 | >=99.997%@0.3um | 1080 | 120 | 1801 | 195 | 2161 | 245 |

| 1170x1170x80 | H14 | >=99.997%@0.3um | 2218 | 120 | 3696 | 195 | 4435 | 245 |

| 1220x610x80 | H14 | >=99.997%@0.3um | 1206 | 120 | 2009 | 195 | 2411 | 245 |

| 320x320x93 | H14 | >=99.997%@0.3um | 166 | 95 | 276 | 160 | 332 | 215 |

| 484x484x93 | H14 | >=99.997%@0.3um | 379 | 95 | 632 | 160 | 759 | 215 |

| 570x570x93 | H14 | >=99.997%@0.3um | 526 | 95 | 877 | 160 | 1053 | 215 |

| 600x600x93 | H14 | >=99.997%@0.3um | 583 | 95 | 972 | 160 | 1166 | 215 |

| 915x610x93 | H14 | >=99.997%@0.3um | 904 | 95 | 1507 | 160 | 1808 | 215 |

| 948x484x93 | H14 | >=99.997%@0.3um | 759 | 95 | 1265 | 160 | 1518 | 215 |

| 1170x570x93 | H14 | >=99.997%@0.3um | 1080 | 95 | 1801 | 160 | 2161 | 215 |

| 1170x1170x93 | H14 | >=99.997%@0.3um | 2218 | 95 | 3696 | 160 | 4435 | 215 |

| 1220x610x93 | H14 | >=99.997%@0.3um | 1206 | 95 | 2009 | 160 | 2411 | 215 |

| 320x320x110 | H14 | >=99.997%@0.3um | 166 | 60 | 276 | 100 | 332 | 135 |

| 484x484x110 | H14 | >=99.997%@0.3um | 379 | 60 | 632 | 100 | 759 | 135 |

| 570x570x110 | H14 | >=99.997%@0.3um | 526 | 60 | 877 | 100 | 1053 | 135 |

| 600x600x110 | H14 | >=99.997%@0.3um | 583 | 60 | 972 | 100 | 1166 | 135 |

| 915x610x110 | H14 | >=99.997%@0.3um | 904 | 60 | 1507 | 100 | 1808 | 135 |

| 948x484x110 | H14 | >=99.997%@0.3um | 759 | 60 | 1265 | 100 | 1518 | 135 |

| 1170x570x110 | H14 | >=99.997%@0.3um | 1080 | 60 | 1801 | 100 | 2161 | 135 |

| 1170x1170x110 | H14 | >=99.997%@0.3um | 2218 | 60 | 3696 | 100 | 4435 | 135 |

| 1220x610x110 | H14 | >=99.997%@0.3um | 1206 | 60 | 2009 | 100 | 2411 | 135 |

| Dimention (W*H*D)mm | Filter class | Efficiency(%) EN1822 | Rated air flow (m3/h) | Initial resistance =<(Pa) | Rated air flow (m3/h) | Initial resistance =<(Pa) |

|---|---|---|---|---|---|---|

| 320x320x69 | U15 | >=99.9997%@0.12um | 111 | 95 | 166 | 145 |

| 484x484x69 | U15 | >=99.9997%@0.12um | 253 | 95 | 379 | 145 |

| 570x570x69 | U15 | >=99.9997%@0.12um | 351 | 95 | 526 | 145 |

| 600x600x69 | U15 | >=99.9997%@0.12um | 389 | 95 | 583 | 145 |

| 915x610x69 | U15 | >=99.9997%@0.12um | 603 | 95 | 904 | 145 |

| 948x484x69 | U15 | >=99.9997%@0.12um | 506 | 95 | 759 | 145 |

| 1170x570x69 | U15 | >=99.9997%@0.12um | 720 | 95 | 1080 | 145 |

| 1170x1170x69 | U15 | >=99.9997%@0.12um | 1478 | 95 | 2218 | 145 |

| 1220x610x69 | U15 | >=99.9997%@0.12um | 804 | 95 | 1206 | 145 |

| 320x320x80 | U15 | >=99.9997%@0.12um | 111 | 85 | 166 | 130 |

| 484x484x80 | U15 | >=99.9997%@0.12um | 253 | 85 | 379 | 130 |

| 570x570x80 | U15 | >=99.9997%@0.12um | 351 | 85 | 526 | 130 |

| 600x600x80 | U15 | >=99.9997%@0.12um | 389 | 85 | 583 | 130 |

| 915x610x80 | U15 | >=99.9997%@0.12um | 603 | 85 | 904 | 130 |

| 948x484x80 | U15 | >=99.9997%@0.12um | 506 | 85 | 759 | 130 |

| 1170x570x80 | U15 | >=99.9997%@0.12um | 720 | 85 | 1080 | 130 |

| 1170x1170x80 | U15 | >=99.9997%@0.12um | 1478 | 85 | 2218 | 130 |

| 1220x610x80 | U15 | >=99.9997%@0.12um | 804 | 85 | 1206 | 130 |

| 320x320x93 | U15 | >=99.9997%@0.12um | 111 | 75 | 166 | 115 |

| 484x484x93 | U15 | >=99.9997%@0.12um | 253 | 75 | 379 | 115 |

| 570x570x93 | U15 | >=99.9997%@0.12um | 351 | 75 | 526 | 115 |

| 600x600x93 | U15 | >=99.9997%@0.12um | 389 | 75 | 583 | 115 |

| 915x610x93 | U15 | >=99.9997%@0.12um | 603 | 75 | 904 | 115 |

| 948x484x93 | U15 | >=99.9997%@0.12um | 506 | 75 | 759 | 115 |

| 1170x570x93 | U15 | >=99.9997%@0.12um | 720 | 75 | 1080 | 115 |

| 1170x1170x93 | U15 | >=99.9997%@0.12um | 1478 | 75 | 2218 | 115 |

| 1220x610x93 | U15 | >=99.9997%@0.12um | 804 | 75 | 1206 | 115 |

| 320x320x110 | U15 | >=99.9997%@0.12um | 111 | 55 | 166 | 80 |

| 484x484x110 | U15 | >=99.9997%@0.12um | 253 | 55 | 379 | 80 |

| 570x570x110 | U15 | >=99.9997%@0.12um | 351 | 55 | 526 | 80 |

| 600x600x110 | U15 | >=99.9997%@0.12um | 389 | 55 | 583 | 80 |

| 915x610x110 | U15 | >=99.9997%@0.12um | 603 | 55 | 904 | 80 |

| 948x484x110 | U15 | >=99.9997%@0.12um | 506 | 55 | 759 | 80 |

| 1170x570x110 | U15 | >=99.9997%@0.12um | 720 | 55 | 1080 | 80 |

| 1170x1170x110 | U15 | >=99.9997%@0.12um | 1478 | 55 | 2218 | 80 |

| 1220x610x110 | U15 | >=99.9997%@0.12um | 804 | 55 | 1206 | 80 |

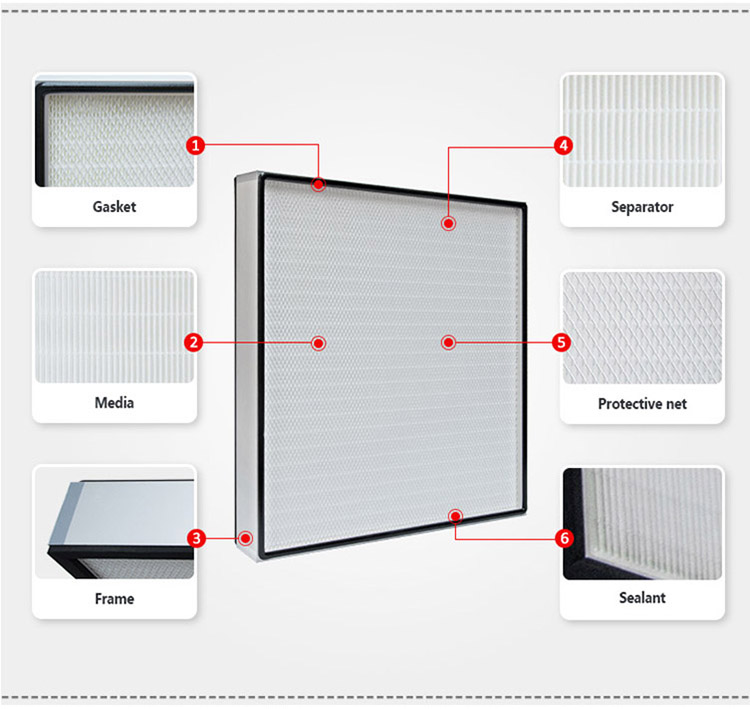

Cleanroom HEPA filters have a lot of things to make them work right in cleanrooms. Let’s talk about some of these things:

Mini Pleat Design: A lot of cleanroom HEPA filters have a mini-pleat design. They make the pleats smaller and closer together. This makes the filter have more filter area than other filters. This makes the filter work better and lets the air move through the filter easier. It saves energy and makes the filter last longer.

Compact Structure: Even though cleanroom HEPA filters are efficient and have a big filtering area, they’re usually built compact. That means they’re good for places where you don’t have a lot of room. But don’t worry, the small size doesn’t mean they’re not going to do a great job. They’re still going to work great, even in tight spaces.

Uniform Airflow: The filter media is pleated, and they use hot-melt separators to keep it in place. This makes sure the air flows evenly across the filter. It also means the filter works the same all the time and doesn’t have any spots where it doesn’t work as well.

Tested and Certified: Every cleanroom HEPA filter is tested and certified. That way, you know it’s going to work great and meet all the efficiency standards. You can trust it to keep your cleanroom clean.

Our Cleanroom HEPA filters have been installed in cleanroom projects in various industries, such as pharmaceuticals, hospitals, semiconductors, chip manufacturing, food production, and precision technology, and have received unanimous praise from customers in over 80 countries.

This proves we’re really good at making cleanroom HEPA filters. When you use our cleanroom HEPA filters, your cleanroom is going to be very clean.

For ISO5 unidirectional flow, an ISO40 H14 cleanroom HEPA filter should be used (minimum penetration particle size particle retention rate 99.99%)

The cleanroom HEPA filter at the end of the air conditioning system (including the separator of the filter) should not use hydrophilic materials, and materials that are easy to breed microorganisms should not be used.

For non-unidirectional flow below ISO5 level, an ISO35 H13 cleanroom HEPA filter should be used (minimum penetration particle size particle interception rate 99.95%).

The filter material of cleanroom HEPA filters is generally glass fiber, but it should not use glass fiber with high sodium and potassium content that is easy to degrade.

Our fast production for you

We want to make sure you get what you need when you need it. That’s why we make our cleanroom HEPA filters fast. That way, you don’t have to wait, and you can keep working.

Delivering to port from factory

Once we make your filters, we put them on a truck and take them to the port. We make it easy for you to get your filters, so you can keep your cleanroom running.

Shipping after customs clearance

After customs, we take care of everything to get your filters to you fast and in great shape. You don’t have to worry about anything. You can just keep working and leave the rest to us.

Last-mile home delivery

After your filters go through customs, we bring them right to your door. We make sure you get your filters fast, so you can make your cleanroom better right away.

Let us know your project and work together.