What are clean room HEPA filters?

It refers to the HEPA filter installed in the clean room at the end of the air filtration systems like FFU(Fan filter units) or other terminal air filtration units. People also call them fan-powered HEPA filters.

It determines the number of particles and the degree of cleanliness in the clean room.

Cleanroom HEPA filters can effectively filter 0.3 microns of particulates with 99.9%(H13, H14) or more filtration efficiency.

Cleanroom HEPA filters can significantly reduce the extra burden of filtration equipment and extend the service life of the equipment.

Since the cleanroom workshop is dust-free and noiseless, humidity and temperature are strictly controlled.

HEPA filters with stable performance and excellent filtration efficiency are widely used in the clean room of manufacturing precision components, semiconductors, pharmaceutical compounding, hospital isolation rooms, etc.

Without cleanroom HEPA filters, the watches people wear in life and the various precision instrumentation used in industry would not be able to operate with precision.

The critical feature of clean rooms

Cleanrooms can maintain extremely low particles such as dust, airborne organisms, or vapourised particles.

A clean room can also refer to any enclosed space where particulate contamination is extremely low, and other environmental parameters such as temperature, humidity, and pressure are controlled within target ranges.

Cleanrooms are also known as the “guardians of high-level manufacturing” due to the demanding production environment required by the technological upgrade of manufacturing.

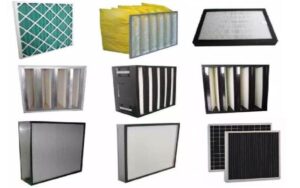

Clean room HEPA filter types

Generally speaking, the cleanroom HEPA filters in everyday use today are mini pleat HEPA filters and Gel seal HEPA filters.

They all use glass fiber media, and only a few users will use synthetic fiber to remove charged particles.

Mini pleat HEPA filter

It has a compact structure, high filtration efficiency, and low resistance, and it is lightweight, safe, and environmentally friendly.

Almost all cleanrooms now use this mini pleat HEPA filter.

Mini pleat HEPA filters use hot melt adhesive to separate the filter media instead of aluminum foil in deep pleat Hepa filters.

The absence of a separator allows a 50 mm thick mini pleat hepa filter to achieve the performance of a 150 mm thick deep pleat HEPA filter.

It can meet the space, weight, contamination control, and energy consumption requirements of today’s air purification. They also can be made in special sizes to meet cleanroom needs.

Gel seal HEPA filter

The gel seal HEPA filter is an upgrade on the pleated HEPA filter. It has an additional gel seal on the frame than the pleated HEPA filter and is. Therefore it is better sealed than the pleated HEPA filter.

It is commonly used in pharmaceuticals, biotechnology, medical device applications, and other industries.

How to choose clean room HEPA filters?

Because of the different industries, each industry has different requirements for clean room air cleanliness and cleanroom filters, and the grade of HEPA air filter chosen is also different.

Due to the different characteristics of clean rooms, the selection of Hepa filters is determined according to the diverse requirements of the clean room level, degree of sterility, temperature, humidity, fire resistance, corrosion resistance, etc.

1. The food packaging, beverage filling, and cosmetic packaging industries have relatively high cleanliness requirements for clean rooms. Clean rooms of class 10,000 – 300,000 are generally used.

Class 10,000 – Class 300,000 clean room purification system, usually using a three-stage air filtration form,

namely G4 primary, F8 intermediate bag, and H13 Hepa air filters.

The coarse and medium efficiency filters are generally placed in the air treatment unit, and the medium efficiency filters are placed in the positive pressure section. In contrast, the Hepa filters are usually located at the end of the purification and air conditioning system.

2. In industries requiring ultra-clean air, such as semiconductors, electronics, military precision instruments, operating theatres, etc., product failure is risky due to a single 0.5-micron particle.

This situation is why the highest demands are placed on air cleanliness for these industries. So clean rooms of the highest cleanliness are used.

For 100 — 10,000 class clean rooms, usually in the filtration system set G4 coarse filter, F8 medium filter, H12 Hepa filter,

The clean room circulation air system also sets the H14 Hepa filter or U15 ULPA filters; that is, four levels of filtration.

3. For small-scale purification equipment such as clean benches, air shower rooms, laminar flow hoods, etc., due to the small volume of air handled, the general air intake surface uses coarse or medium-effect filters, and the air supply end must choose H13-H14 Hepa filters or U15 ULPA filters;

Generally, to save costs and get sound contaminant reduction and operating efficiency, companies will set up a class 100 laminar flow hood inside a class 10,000 clean room or set up FFU(a device that uses energy-efficient dual motorized impellers with variable speed control to provide unidirectional airflow).

Rule of thumb for replacements

The cleanroom has strict regulations on the humidity, temperature, amount of fresh air, status, and the environment’s illumination to ensure the quality of the products and the comfort of the personnel working environment.

The whole clean room system is equipped with a three-stage filter system using primary, medium, and Hepa filters to control the number of dust particles in the clean area and the number of settling bacteria and floating bacteria, etc.

As the end filtration device, the Hepa filter determines the operating effectiveness of the whole purification system. It is crucial to grasp the replacement time for the Hepa air filters.

When to replace the Cleanroom Hepa filter?

According to the number of air dust particles with particle size greater than or equal to 0.5μm allowed to exist in the air after cleanliness, the clean room can be divided into 100000 level, 10000 level, 1000 level, 100 level, etc. Where the higher the number, the lower the cleanliness level.

- Suppose the resistance has exceeded the rated initial resistance of 60 Pa, is equal to 2 x the design or operating initial resistance, or has been running for 3-6 months. In that case, the medium efficiency filter(f6-f9) must be replaced at any time.

- If the resistance exceeds the rated initial resistance of 80 Pa or is equal to 2 x the design or initial resistance, or if the filter has been in operation for 6-12 months, the sub-high efficiency filter(H10-H12) should be replaced at any time.

- Suppose the resistance exceeds the rated initial resistance of 100 Pa or is equal to 2 x design or operating initial resistance or has been in operation for over 12 months. In that case, the Hepa filter(H13-H14) should be replaced anytime.

- Suppose the resistance exceeds the rated initial resistance of 160 Pa or is equal to 2 x design or operating initial resistance or has been in operation for more than 24 months. In that case, the ultra-high efficiency filter(U15-U17) should be replaced anytime.

Maintaining Your Cleanroom’s HEPA Filter

The clean room Hepa filter is the core of the entire clean equipment system. Cleanroom specialists must carefully maintain and repair it with practical and feasible measures and programs in place.

1. Ventilation hoods should be cleaned once a week.

2. The condition of the ventilation fan should be tested weekly.

3. Filtration equipment is regularly inspected, repaired, and maintained to ensure the filtration equipment’s regular operation and good performance.

4. The primary and secondary filters should be tested every 30 days, and it is advisable to have a spare set in case of unexpected situations.

Depending on the use, the primary and secondary filters should be replaced every 3 to 6 months, and the filters should be dry before replacement.

The filtration equipment should only be run after the primary and secondary filters are installed to extend the life of the more expensive Hepa filters.

At the same time, the cleanliness of the environment around the clean room, the regular operation of the air supply filtration system, and the strict use of management norms are also the keys to prolonging the service life of the Hepa air filters.

How to install the clean room Hepa filter?

The HEPA filter is a vital component of the air cleaning system. It uses ultra-fine glass fiber paper to filter particles of up to 0.3μm that cannot be filtered by the primary and secondary filters, ensuring the cleanliness of the clean room.

1. To ensure the filtration efficiency of the Hepa filter and the cleanliness of the clean system, the installation of the HEPA filter must comply with the requirements of the design drawings or the relevant operational specifications.

Preparation before installation: in order to prevent contamination of the HEPA filter, the following steps must first be completed when opening the filter’s box for inspection and installation

- The air cleaning system is installed.

- The air conditioner, the high-efficiency filter box, the air duct, and the clean room have been cleaned.

- The dust blown out of the air conditioning system is stabilized after the test run of each piece of equipment and the air ducts.

Before installation, check the straightness of the frame or end face of the Hepa filter. The deviation of the flatness of the end face should not be greater than 1mm per unit.

Suppose the flatness of the end surface exceeds the permissible deviation. In that case, it is only allowed to modify or adjust the end surface of the frame where the filter is installed, not to modify the outer frame of the filter itself. Otherwise, it will damage the filter media or the sealing part of the filter and reduce the filtration effect.

2. When installing Hepa filters in clean rooms, ensure that the airflow direction is consistent with the direction of the arrow mark on the outer frame of the filter.

3. The seal of the clean room Hepa filter frame is usually made of closed-cell sponge rubber or neoprene and is also sealed with a silicone rubber coating.

The thickness of the sealing gasket is often 5mm, pasted on the filter frame, and the compression rate after installation should be 25% ~ 30%.

The seal of the clean room Hepa filter and the installation frame must keep the negative pressure pipe open.

How long do cleanroom HEPA filters last?

The service life of the HEPA filter depends not only on itself, like filter material, filter area, structural design, and initial resistance, but also on the concentration of dust in the air, the actual air volume used, the setting of the final resistance, and other factors.

The clearest point is that the life of the Hepa filter is related to its final resistance.

In order to grasp the life cycle of a high-efficiency filter, it is essential to understand the changes in its resistance. Something must be understood as follows.

Rated initial resistance: At rated airflow, the initial resistance is provided by the Hepa filter sample, characteristic curve, or Hepa filter test report.

Design initial resistance: Hepa filter resistance at the system design airflow (should be provided by the air conditioning system designer).

The initial resistance of operation: the resistance of the filter at the beginning of system operation. If there is no instrument to measure the pressure, the resistance under the design air volume can only be taken as the initial resistance of operation (the actual air volume of operation cannot be precisely the design air volume)

Factors to determining the final resistance of a Hepa filter

Set low Hepa filter resistance.

If the Hepa filter final resistance is set low, the service life will be short, the filters will be replaced quickly (filter costs, labor costs, and disposal costs), and the maintenance costs will be correspondingly high.

However, the energy consumption for operation is low, so each filter should have the most economical final resistance value.

The dirtier the filter, the faster the resistance increases.

Set high Hepa filter resistance.

A high final resistance does not mean a longer Hepa filter life, but a high resistance can drastically reduce airflow in the air conditioning system.

Inadequate air supply to the entire filter system will affect the number of air changes in the clean room and prevent cleanliness requirements from being met. It also brings higher costs. Excessive final resistance is not desirable.

Under reasonable circumstances, the final resistance of a HEPA filter is 1.5 to 2 times its initial resistance.

The life of a Hepa filter is over when it reaches its final pressure drop.

Why is HEPA filter replacement frequency such a vital issue?

For an operating cleanroom, the value of the end HEPA filters is low. They may not add up to the output of the user for a few hours – but the risks and overheads of replacing the end HEPA filters can be high.

When replacing the Hepa filter, production has to be stopped, and the owner himself can only calculate the stoppage loss, and this loss is undoubtedly higher than the cost of spare parts for the filter.

Replacing a Hepa filter is a meticulous operation, and anything in a clean room can be expensive, and damage to one component can cost more than the entire filter.

That’s why it’s essential to choose an air filter manufacturer with consistent quality and professional service, and we can help you with that.