What is an Activated Carbon Air Filter?

Activated carbon air filters have a powerful ability to adsorb and remove chemical volatiles, gaseous pollutants, and odors, while the activated carbon inside the filter plays a key role.

What does an activated carbon air filter do?

Activated carbon air filters are mainly used for gas adsorption.

- It can absorb volatile organic compounds such as benzene, acetone, xylene, toluene, CS2, oil gas, etc.

- Smoke odor, decoration deodorization, indoor air purification (removal of formaldehyde, benzene, etc. ).

- Effective in removing common pollutants, odors, volatiles, bacteria, and viruses from paint spray booths and electronics factories.

- Filters and adsorbs odors from food processing plants and hospitals.

- It is widely used to treat organic gases such as phenols, esters, alcohols, aldehydes, and malodorous gases containing toluene, xylene, and benzene, as well as various low-concentration, high-air volume gases containing trace amounts of heavy metals. The exhaust gases can be directly discharged after adsorption, concentration, and purification.

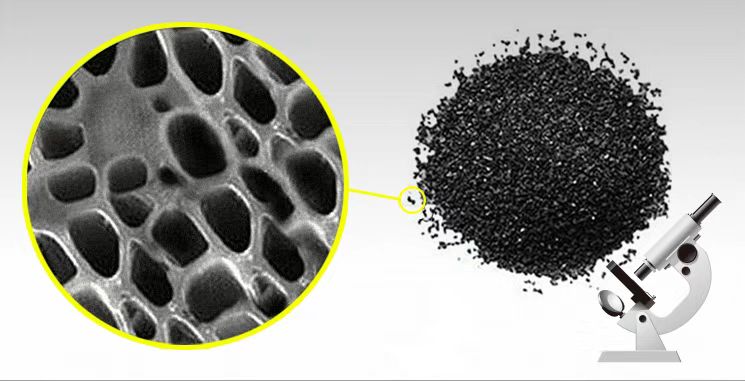

Activated carbon is the core component of an activated carbon air filter.

In all activated carbon filters, the activated carbon inside the filter can absorb gas pollutants or odors; therefore, activated carbon is the heart of the filter.

What is activated carbon?

Ordinary charcoal and coke are inherently porous, and ordinary charcoals were first used as adsorbent materials.

In order to increase the adsorption performance, ordinary charcoal is “activated” to make the charcoal micro-pores smaller, and the activated charcoal is called activated carbon.

Activated carbon is a porous carbon with a vibrant pore structure. It has good adsorption characteristics, its adsorption effect by physical and chemical suction force, and its appearance is black.

Raw materials of activated carbon

Activated carbon is mainly made of substances with high carbon content, such as wood, coal, fruit shells, bone, petroleum residue, etc.

Coconut shell is the most commonly used raw material for activated carbon. Under the same conditions, the coconut shell’s active quality and other characteristics are the best because it has the largest specific surface.

Activated carbon types

Coconut shell activated carbon

As its name suggests, coconut shell activated carbon is made from high-quality coconut shells from Southeast Asia and other places. The raw material is refined after the screening, carbonization by water vapor, and then made by a series of processes such as debonding, activation, and sieving.

Coconut shell activated carbon appearance as black grain, with a well-developed pore structure, high adsorption capacity, strength, stable chemical properties, and durability.

It is widely used in metallurgy and chemical industries, deep purification of industrial water, and refining precious metals.

Regarding odor purification and filtration, coconut shell activated carbon is the first choice.

Fruit shell activated carbon

Fruit shell activated carbon is mainly made from fruit shells and wood chips, which are carbonized, activated, and refined.

It has the advantages of good abrasion strength, well-developed voids, high adsorption performance, high strength, easy regeneration, economical and durability, etc.

It is used for exhaust gas purification and recovery, for the purification of harmful gases emitted in industry, e.g., desulphurizing waste flue gases, recovery of volatile and dissipated solvents such as acetone, esters, benzene, petrol, etc.

It is also used for defense against poisonous gases and harmful vapors.

In the defense and civil industries, fruit shell activated carbon is used to fill various gas masks and manufacture textiles to protect against radioactive substances.

Wood activated carbon

It is made of high-quality wood in powder form, refined by high-temperature carbonization, activation, and various processes.

It has a large specific surface area, high activity, strong decolorization force, and a large pore structure.

It can effectively adsorb various substances and impurities in liquids.

The appearance and shape of activated carbon

Powdered activated carbon

Activated carbon with more than 90% passing through a standard 80 mesh sieve or with a particle size of less than 0.175mm is generally referred to as powdered activated carbon or pulverized carbon.

Powdered carbon has the advantage of faster adsorption and fuller use of adsorption capacity when in use.

With advances in separation technology and the emergence of specific application requirements, there is a tendency for the particle size of powdered carbon to become more and more refined, in some cases reaching the micron or even nano level.

Granular activated carbon

Activated carbon with a particle size greater than 0.175mm is usually called granular activated carbon.

Granular carbon contains columnar carbon, spherical carbon, etc.

They are usually filled directly into some breathable non-woven bags or shells, increasing the adsorption capacity and enhancing the adsorption effect.

Features and functions of activated carbon

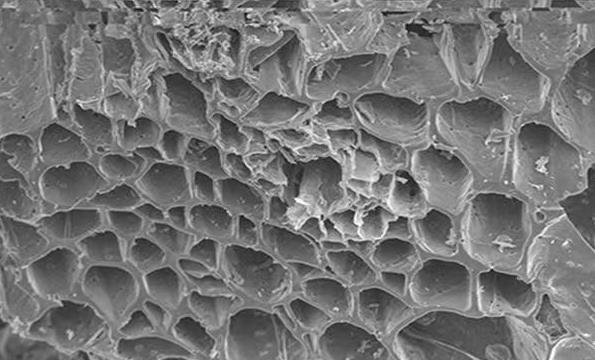

Activated carbon is activated to form delicate pores of various shapes and sizes. It can significantly increase the specific surface area and improve the adsorption capacity.

The radius of activated carbon’s pores is 1-11,000nm, the radius of tiny pores is below 2-3nm, the radius of medium pores is generally 3-99nm, and the radius of large pores is 99-11,000nm.

The small pore volume is generally 0.149-0.91mL/g, the medium pore volume is generally 0.021-0.11mL/g; the large pore volume is generally 0.21-0.51mL/g.

The physical properties of activated carbon

Activated carbon has a vibrant pore structure and good adsorption properties.

Its structure resembles a hexagonal shape, and its irregular hexagonal structure determines its multi-pore structure and high surface area.

Each gram of activated carbon has a specific surface area of 1000 square meters.

The enormous specific surface area and fine pores are essential for the adsorption of gases and odors.

The chemical properties of activated carbon

The adsorption properties of activated carbon are not only related to its pore structure but also to its chemical composition.

The main element of activated carbon is carbon, which generally has around 90-95%.

Oxygen and hydrogen are mostly combined with carbon atoms in a chemical bond to form organic functional groups, with an oxygen content of 4-5% and a hydrogen content of around 1-2%.

During the activation reaction in manufacturing activated carbon, the micropores are further enlarged to form many pores of different sizes.

Part of the pore surface is burnt off, and the chemical structure becomes defective or incomplete.

In addition, the presence of ash and other heteroatoms creates defects and unsaturated bonds in the basic structure of the activated carbon.

Oxygen and other heteroatoms are adsorbed onto these defects and react with carbon on the surface and edges to form various bonds, resulting in the formation of different surface functional groups, thus giving the activated carbon a wide range of adsorption properties.

The production process of activated carbon

The production of activated carbon has two processes.

1. Charring, the raw material is dried at a temperature of 180 to 601 degrees, while 80% of its organic tissue is charred.

2. Activation, the charred material from the first step is fed into a reaction furnace, which reacts with the activator and water vapor to complete the activation process and produce a finished product.

During the activation process, the charring material is heated to a suitable temperature (810 to 1010 degrees) after removing all other decomposable materials, resulting in a profound pore structure and an enormous specific surface area, giving the activated carbon a powerful adsorption capacity.

Activated carbon produced from different raw materials has different pore sizes, of which activated carbon made from coconut shells has the smallest pore size, and wood activated carbon has a larger pore size. Coal-activated carbon has a pore size between the two.

Choosing the right activated carbon

The corresponding activated carbon must be selected for different adsorption objects based on the above characteristics.

Therefore, coconut shell activated carbon with a small pore size should be used in gas adsorption.

In liquid phase adsorption, other activated carbons with larger pore sizes are often chosen.

Types of activated carbon air filters and filter media

There are many types of activated carbon air filters with different filter materials depending on the use required.

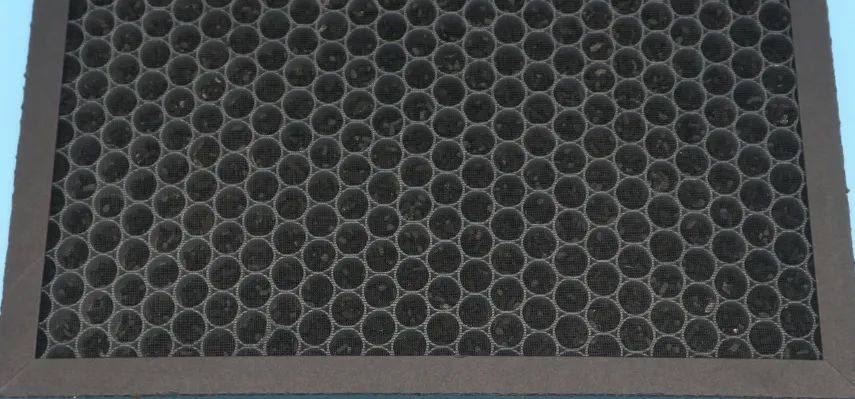

Honeycomb panel activated carbon filter.

The activated carbon honeycomb panel filter uses aluminum honeycomb, plastic honeycomb, and paper honeycomb with a through-hole structure as the carrier. It fills the honeycomb holes with activated carbon granules.

Compared with the traditional activated carbon filter, it has good gas dynamics, small bulk density, large specific surface area, high adsorption efficiency, and a slight wind resistance coefficient.

It can adsorb harmful gases (TVOC), and deodorization efficiency can reach 95% or more.

It is filled with activated carbon granules.

Honeycomb panels can be filled with different types of activated carbon, such as shell activated carbon, coconut shell activated carbon, etc.

Depending on the customer’s needs, the activated carbon can also be treated by the manufacturer with formulas to improve its performance in removing certain harmful gases, such as formaldehyde, ammonia, benzene, etc.

Benefits of Having Activated Carbon Filters for Air Purifiers

Honeycomb panel activated carbon filters are mainly used in air purifiers, in conjunction with pre-filters and HEPA filters, to remove air pollutants, volatile organic compounds, particles, pet dander, smoke, and odors and improve air quality.

Medium or HEPA pleated activated carbon air filter.

This activated carbon air filter uses mainly laminated carbon filter material made by a hot melt glue and a mini pleat process.

It combines the advantages of HEPA filter media and activated carbon to remove odors and adsorb harmful gases and achieve efficient filtration.

It is mainly used as a car cabin filter.

Laminated carbon filter material

Also called Sandwich Carbon Cloth.

It has five layers of composite material.

The first layer is the base layer non-woven.

The second layer is coconut shell activated carbon grains evenly spread.

The third layer is pp non-woven.

The fourth layer is composite needle-punched cotton.

The fifth layer is the base layer non-woven.

After high-temperature hot pressing, it forms a composite together.

Instead of the traditional large granules of carbon, the sandwich fabric uses broken small granules of carbon, equivalent to smashing the carbon directly into the middle of the HEPA.

Increasing the total surface area of the carbon particles without increasing the amount of carbon, thus significantly increasing the single adsorption efficiency.

As the small granules of carbon are more evenly distributed in the non-woven fabric and the voids are large enough, the wind resistance is low enough. So the noise level is correspondingly low simultaneously as the air volume increases.

Activated carbon filter foam

It is made of powdered activated carbon attached to the fiber substrate.

The activated carbon is integrated into every fiber by impregnation and hot fusion.

The activated carbon filter foam has high carbon content, good permeability and absorbency, and a good dust collection capacity.

It can be cut, folded, and stamped into custom-made shapes.

It can effectively remove airborne dust, ozone, odors, and organic pollutants and is widely used in ventilation systems, paint booth exhaust systems, industrial waste gas purification, HVAC, household and vehicle cabin filter, air filters, gas phase adsorption, and so on.

It is also the filter material for activated carbon panel and pocket filters.

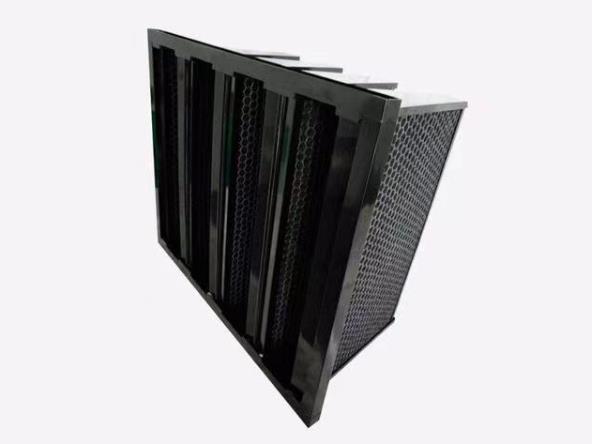

Activated carbon panel air filters, activated carbon pocket air filters, and activated carbon V-BANK air filters

Generally used activated carbon felt or activated carbon filter cotton as filter material, it has a large surface area, strong adsorption capacity, fast adsorption speed, and good purification effect.

It is mainly used to remove gases, volatile vapors, and smoke, and eliminating odors increases the proportion of returned air to the room.

They are mainly used for the primary filtration of chemical and industrial ventilation and air conditioning systems, the purification and filtration of available indoor ventilation systems, and the pre-filtration of household air conditioning and purification equipment.

They are particularly effective in dealing with odors and air pollution in air conditioning and ventilation systems and can effectively clean the air. Removal of odors from electronic components and food processing plants; smells from hospitals and museums; paint odors from paint spraying workshops.

Notes on the selection of activated carbon air filters

The actual choice of activated carbon air filter should be based entirely on the type of pollutant, its concentration, and the air volume to be treated to determine the form of filter and the sort of activated carbon.

In the meantime, the upstream and downstream of the activated carbon filter should have a good dust removal filter whose efficiency specification should be no less than F7.

The upstream filter mainly prevents dust from blocking the activated carbon air filter; the downstream filter stops the dust generated by the activated carbon filter.