Selecting the right industrial air filter starts with knowing your environment and the contaminants you face. You might encounter dust from sanding or grinding, oil mist from machinery, water vapor from humid processes, or even microbial contaminants from people and materials. Each type of contaminant can cause problems like clogged equipment, sticky residues, corrosion, or health hazards. When you match filter type, efficiency, and size to your specific needs, you protect your equipment and meet regulations. Choosing the wrong filter often leads to equipment damage, higher costs, or non-compliance.

Key Tips

- Assess your specific application needs before choosing an air filter. Consider the environment, processes, and contaminants present to avoid costly mistakes.

- Understand the types of contaminants in your facility. Identifying these helps you select the right filter type, ensuring effective air quality management.

- Define clear air quality goals based on industry standards and employee health. This helps you choose filters that meet both legal requirements and comfort levels.

- Know the difference between MERV and HEPA ratings. Higher ratings indicate better filtration efficiency, crucial for environments needing high air purity.

- Regularly replace filters every 3–6 months to maintain system performance. Timely replacements prevent clogs and ensure compliance with safety standards.

Filtration Needs

Application Assessment

You need to start by assessing your specific application. Every industrial setting has unique requirements, so you must look at the environment, the processes involved, and the size of the area that needs filtration. Different industries, such as manufacturing, food processing, or healthcare, face different challenges. For example, pharmaceutical and biotech facilities require ultra-pure filtration to maintain sterility, while automotive plants need heavy-duty systems to remove dust and fumes.

To guide your assessment, consider these key factors:

- The type of processes and equipment in use

- The volume of air that needs to be filtered

- The layout of your facility and possible airflow patterns

- The number of filtration points needed for optimal results

You can use several methods to evaluate your needs:

| Method | Description |

|---|---|

| CFM Rating | Calculate the cubic feet per minute (CFM) by dividing the space size by the air exchange rate (AER). |

| Ease of Installation and Mobility | Choose a system that is easy to install and can be moved if your business changes. |

| Efficiency | Select a high-efficiency system that balances performance with cost-effectiveness. |

Facility managers must also follow specific standards to ensure indoor air quality meets safety requirements. This is especially important in industries with strict air quality standards.

Tip: Assessing your application thoroughly helps you choose the right industrial air filter and avoid costly mistakes.

Contaminant Types

Identifying the types of contaminants in your facility is a crucial step. Each industry deals with different substances, such as chemicals, particulates, gases, or liquids. You need to know what you are filtering out to select the right filter.

Common tools and technologies for identifying contaminants include:

- Analytical kits for quick chemical tests

- X-ray fluorescence instruments for detecting metals

- Direct-push platforms for subsurface sampling

- Gas chromatography for separating complex mixtures

- Real-time monitoring systems and wearable sensors for continuous data

In manufacturing environments, you may encounter several contaminant types:

| Contaminant Type | Description | Control Measures |

|---|---|---|

| Chemical Contamination | Substances like lubricants and cleaning agents that can contaminate products | Regular equipment checks, proper rinsing, and testing for residues |

| Physical Contamination | Foreign materials such as plastic, metal, and organic matter | Use of detection equipment, sifting ingredients, and following Good Manufacturing Practices (GMP) |

| Microbial Contamination | Harmful microorganisms that can cause illnesses | Sanitation protocols, employee training, and environmental monitoring |

| Allergenic Contamination | Allergens crossing into non-allergen products | Segregation of environments and proper sanitation between production runs |

| Environmental Contamination | Pollutants from agriculture and industrial activities | Supply chain transparency, ingredient testing, and alternate sourcing |

Selecting the correct industrial air filter depends on understanding these contaminants. For example, HEPA and ULPA filters are necessary in healthcare and laboratory settings to prevent contamination.

Air Quality Goals

You should define clear air quality goals for your facility. These goals depend on your industry, the health and comfort of your employees, and any regulatory requirements. Some organizations aim for the highest possible indoor air quality, while others focus on meeting minimum legal standards.

Common air quality standards include:

| Standard | Description |

|---|---|

| ISO 8573.1 | Sets purity levels for compressed air |

| ISO 12500 | Addresses the filtration of contaminants in compressed air |

You may also need to comply with:

- OSHA workplace air quality standards

- EPA’s 40CFR – Part 63.11173

- Guidelines from Underwriters Laboratories and the National Fire Protection Association

Effective smoke removal is essential for complying with occupational safety regulations, maintaining good indoor air quality, and ensuring the well-being of employees and patrons.

When setting your air quality goals, weigh the effectiveness, efficiency, and cost of each industrial air filter. Consider the specific needs of your organization and the comfort of everyone in the facility. Understanding the application and performance expectations of each filter helps you make the best decision for your building.

Industrial Air Filter Efficiency

MERV and HEPA Ratings

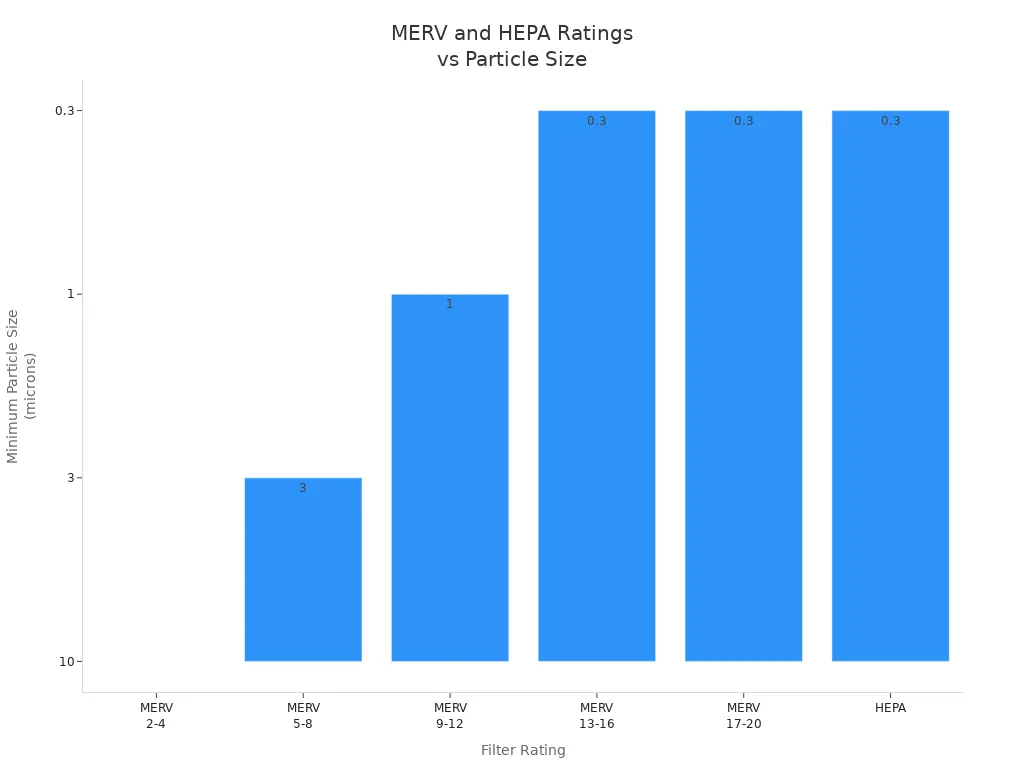

When you choose an industrial air filter, you need to understand MERV and HEPA ratings. These ratings tell you how well a filter can capture particles of different sizes. MERV stands for Minimum Efficiency Reporting Value. Higher MERV ratings mean the filter can trap smaller particles and improve air quality. HEPA filters go even further. They have a MERV rating of 17 or higher and can capture at least 99.97% of particles that are 0.3 microns or larger.

- MERV ratings directly affect a filter’s ability to capture particles and influence air quality.

- Understanding MERV ratings helps you select the right filter for your needs, ensuring cleaner air and better HVAC performance.

- HEPA filters are best for environments that need the highest air purity, such as hospitals and cleanrooms.

You can use the following table to match MERV and HEPA ratings to different industrial applications:

| MERV Rating | Application | Particle Size (microns) |

|---|---|---|

| 2-4 | Commercial settings (textile, sawdust, pollen) | ≥ 10 |

| 5-8 | Commercial and industrial workplaces (mold, bacteria) | 3 – 10 |

| 9-12 | Medical facilities, commercial, and industrial | 1 – 3 |

| 13-16 | Hospital rooms, vet clinics (smoke, pet dander) | 0.3 – 1.0 |

| 17-20 | Highest rated filters (viruses, allergens) | < 0.3 |

| HEPA | Removes at least 99.97% of particles | 0.3 |

Tip: For sensitive environments like hospitals or laboratories, always choose a filter with a higher MERV or HEPA rating.

Micron Rating & Surface Area

The micron rating tells you the smallest particle size a filter can remove. If you need to capture specific contaminants, you must pay attention to this number. For example, a one-micron filter can remove almost all common particulates, including bacteria and mold spores, which usually range from 2 to 10 microns. This makes micron rating a key factor in choosing the right industrial air filter for your facility.

- Micron rating determines the size of particles that can be filtered, which is crucial for capturing specific contaminants.

- A one-micron filter can potentially remove 100% of common particulates, including bacteria and mold spores.

- The filter surface area affects how much particulate matter the filter can hold and how often you need to replace it.

If you double the filter surface area, you can reduce pressure drop by over 50%. This means your system will use less energy and the filter will last longer. You should also keep the filter face velocity between 200-250 feet per minute for the best air interaction.

| Contaminant Type | Micron Rating | Removal Efficiency (%) | Notes |

|---|---|---|---|

| Pesticides | Varies | 80-100% | Hydrophobic pesticides removed most easily |

| Organochlorine Insecticides | Varies | 93% average, 100% for endosulfan | High rejection for persistent types |

| Less Hydrophobic Pesticides | Varies | <80% for dimethoate, 38% for monocrotophos | Lower removal rates observed |

Note: High particle removal efficiency is especially important for hydraulic systems and other sensitive equipment.

Airflow & Capacity

You must match your filter’s airflow and capacity to your system’s needs. Proper airflow keeps dust and particles suspended, so they do not settle in ducts or equipment. If the airflow is too low, contaminants can build up and cause problems.

Proper air velocity ensures that dust stays suspended and doesn’t settle in the ducts. The conveying air must reach a minimum air conveying velocity to transport the dust effectively.

To calculate airflow, use the formula:

CFM (Cubic Feet per Minute) = Area × Velocity

This formula helps you determine the right airflow rate for your industrial air filter. You can follow these steps:

- Identify the area of the bottom of the dust collector’s filter bags.

- Multiply the area by the number of filter bags.

- Divide by the volume to find the can velocity.

Several factors determine the required filter capacity:

| Factor | Description |

|---|---|

| Filter Size, Shape, and Form | Must fit your equipment and facility requirements. |

| Types of Air Contaminants | Choose filters for specific pollutants, such as gases or fine dust. |

| Volume of Contaminants | Larger facilities with more output need bigger filters. |

| Physical Characteristics | Filters must handle the type of dust or pollutants produced, such as explosive or moist dust. |

| Type of Filter Media | The media affects performance; sometimes you need custom solutions. |

| System Pressure | Filter size influences pressure; too small causes drops, too large may be unnecessary. |

Remember: Matching filter capacity to your system ensures efficient operation and helps you avoid costly downtime.

Filter Type & Fit

Disposable vs. Reusable

You face a choice between disposable and reusable filters when selecting an industrial air filter. Each option offers unique benefits and drawbacks. Disposable filters provide excellent filtration for small particles, sometimes as tiny as 0.3 microns. These filters work well for improving indoor air quality and suit environments where allergies or sensitive equipment matter. You may find disposable filters affordable at first, but frequent replacements can increase costs over time. Replacing a disposable filter every three months means you buy four filters each year, which may cost more than a reusable filter.

Reusable filters help you save money in the long run. You can clean and reuse them, which reduces landfill waste and supports sustainability. Some reusable filters feature antimicrobial protection and high MERV ratings, boosting air quality. You must maintain reusable filters regularly, which may require extra effort. If you want a filter that lasts and supports green practices, reusable options make sense.

Tip: Choose disposable filters for maximum particle removal and convenience. Pick reusable filters if you want lower long-term costs and less environmental impact.

You can compare the main features:

- Reusable filters reduce expenses over time and support sustainability.

- Disposable filters offer high filtration efficiency for small particles.

- Disposable filters create more waste and may cost more with frequent replacements.

- Reusable filters need regular cleaning and maintenance.

Dimensions & Compatibility

You must match the filter dimensions to your system for proper fit and performance. Industrial air filters come in many sizes, so you need to check the specifications before buying. Standard dimensions range from 24″ x 24″ up to 48″ x 48″, with thicknesses from 4″ to 12″. These measurements affect how well the filter fits your equipment and how much air it can handle.

| Dimension Range | Thickness Range |

|---|---|

| 24″ x 24″ to 48″ x 48″ | 4″ to 12″ |

You also need to consider the type of filter that suits your application. Here are some common types and their advantages:

- HEPA and ULPA filters capture 99.97% of ultra-fine particles, ideal for cleanrooms and pharmaceutical production.

- Activated carbon filters remove gases and odors, making them essential in labs and paint booths.

- Metal mesh and washable filters offer durability and can be reused, which helps with sustainability.

- Custom filters provide solutions for special needs, such as handling acidic gases.

Note: Always check your system’s requirements and choose a filter that matches both the size and the type needed for your environment.

Compliance

Industry Standards

You need to understand industry standards before you select an industrial air filter. Standards help you compare products and ensure you meet safety and performance goals. The ISO 16890 standard now sets the benchmark for air filters worldwide. This standard replaced EN 779 and classifies filters by how well they capture particulate matter like PM1, PM2.5, PM10, and coarse dust. Filters must achieve at least 50% effectiveness for each particle group to earn an ISO 16890 classification.

| Standard | Description |

|---|---|

| ISO 16890 | Current international standard for air filters, replacing EN 779. |

| Classification | Filters are categorized by efficiency for PM1, PM2.5, PM10, and coarse dust. |

| Legal Binding | Standards are voluntary unless required by law or contract. |

| Efficiency | Filters must reach 50% effectiveness for PM groups to qualify. |

Different industries follow unique standards. The cement industry faces strict rules because of high emissions. You see similar pressure in food processing and pharmaceuticals, where advanced filtration helps meet environmental targets. Many sectors now invest in better dust control to comply with laws like the Clean Air Act in the USA or the EU’s Industrial Emissions Directive.

Tip: Always check which standards apply to your sector before you choose a filter. This helps you avoid costly mistakes and ensures you meet legal requirements.

Regulatory Requirements

You must follow regulatory requirements to keep your facility safe and legal. Rules cover many areas, from oil mist collection in CNC machining to fume extraction in metal grinding. You also need to meet fire safety codes and containment classes, especially if you use HEPA filters in nuclear or hazardous settings.

| Requirement | Description |

|---|---|

| Fire Ratings | Filters and housings must meet fire safety codes. |

| Containment Classes | HEPA filters must comply with strict containment rules. |

You also need to pay attention to exposure limits and health guidelines:

- Compliance with OSHA permissible exposure limits (PELs)

- Adherence to ACGIH Threshold Limit Values (TLVs)

- Following NIOSH best practices for air quality and health

If you ignore these rules, you risk serious consequences:

- Legal penalties, including fines and criminal charges

- Financial losses that can reach millions of dollars

- Administrative actions like warning letters and forced compliance schedules

- Suspension or loss of operating licenses for repeat violations

- Damage to your reputation in the community

You protect your business and your employees when you follow these regulations. Choosing the right industrial air filter helps you stay compliant and avoid costly problems.

Maintenance & Cost

Replacement Frequency

You need to replace your filters regularly to keep your system running smoothly. In high-use environments, most facilities change their filters every 3–6 months. This schedule helps prevent clogs, keeps air quality high, and protects your equipment from damage.

- Changing filters on time reduces the risk of system breakdowns.

- Regular replacement supports compliance with safety standards.

- You can plan filter changes during routine maintenance to save time.

Tip: Set reminders for filter replacement to avoid unexpected downtime and maintain consistent performance.

Operational Costs

Operational costs can vary based on the type of filter and your specific application. You should consider several factors when calculating the total cost of ownership. The table below outlines the main cost drivers:

| Factor | Description |

|---|---|

| Energy Consumption | The electricity required to operate the filtration system; high-efficiency units may have lower energy consumption despite higher upfront costs. |

| Maintenance and Servicing | Regular tasks such as cleaning and inspections to ensure optimal performance. |

| Filter Replacement | The frequency of replacing filters varies by type and environmental conditions, impacting overall costs. |

You can lower costs by choosing filters that match your system’s needs and by maintaining them properly. High-efficiency filters may cost more at first, but they often save money over time by using less energy and lasting longer.

Environmental Impact

The environmental impact of your filtration system depends on the materials, energy use, and disposal methods. Many filters use synthetic fibers from non-renewable resources, which increases carbon emissions during production and disposal. Sustainable options, such as filters made from recycled or natural materials, can help reduce this impact. Energy use during operation also matters, especially if your facility relies on fossil fuels. Good maintenance and recycling practices help minimize waste and support sustainability.

You can take steps to reduce your environmental footprint:

- Use biodegradable or recyclable filter materials, such as cellulose or bamboo fibers.

- Choose energy-efficient filters and consider smart sensors or solar-powered systems.

- Support manufacturers that use energy-efficient production methods and zero-waste policies.

Note: Selecting the right industrial air filter and maintaining it well not only saves money but also helps protect the environment.

Choosing the right industrial air filter protects your workplace and supports compliance with EPA and OSHA standards. You should follow a systematic approach:

- Understand your application requirements.

- Know the filtration efficiency.

- Consider flow rate and pressure compatibility.

- Check material compatibility.

- Assess environmental conditions.

- Select the best filter type and technology.

If your needs are complex, consult experts or suppliers. Review your current filtration systems regularly to optimize performance and maintain a healthy, efficient environment.

FAQ

What is the difference between MERV and HEPA filters?

MERV filters trap particles based on a numbered scale. HEPA filters capture at least 99.97% of particles as small as 0.3 microns. You should choose HEPA for the highest air purity.

How often should you replace industrial air filters?

You should replace most industrial air filters every 3–6 months. High-use environments may need more frequent changes. Always check manufacturer guidelines for your specific filter.

Can you reuse industrial air filters?

Some filters are reusable. You can clean and reinstall them. Disposable filters must be replaced. Always follow the manufacturer’s instructions to avoid damaging your system.

What contaminants do industrial air filters remove?

Industrial air filters remove dust, fumes, oil mist, smoke, bacteria, and allergens. You should select a filter based on the contaminants present in your facility.

How do you know which filter size fits your system?

Check your equipment’s specifications. Measure the filter slot’s length, width, and thickness. You should match these dimensions to the filter for proper fit and performance.