From their initial use as silk to filter medicinal herbs to their current widespread application in everyday life and production, the evolution of air filters reflects the increasingly stringent environmental demands placed on us in both daily life and production.

Air filters have become a fixture in steel, chemical, cement, nonferrous metallurgy, semiconductor production, cleanrooms, and homes. But what are the primary problems that air filters address in these applications? Let’s find out.

1. Air Filtration in the Steel Industry

In steel production, high-temperature flue gas and dust from blast furnaces, electric furnaces, converters, and sintering furnaces are the primary sources of pollution. China’s annual steel production exceeds 100 million tons, and with over 1,600 steel companies nationwide, the sheer volume of dust and smoke emitted is self-evident.

This is also the primary reason why the steel industry is the largest user of air filtration materials. The most commonly used filtration product in the steel industry is woven or non-woven high-temperature resistant bag filters, which account for over 70% of the dust collectors used in the industry.

2. Air Filtration in the Cement Industry

The primary source of pollution from the cement industry comes from dust-laden gases. These gases vary depending on the process, ranging from ambient temperature dust to high-temperature, high-humidity, high-concentration, flammable, and explosive dust.

Thus, while cement companies widely utilise bag filters, the filter materials used cannot be generalised. Common filter materials include glass fiber, bulked glass fiber yarn, polyester needle-punched felt, and coated filter media.

Globally, cement manufacturers emit over 10 million tons of dust and smoke into the atmosphere annually, making the cement industry the second-largest user of air filters. Although recent environmental improvements have resulted in the phasing out of a number of cement plants with outdated processes and severe environmental pollution, the overall environmental governance task remains daunting.

3. Air filtration in the non-ferrous metallurgical industry

The nonferrous metallurgy industry is the third-largest user of industrial filtration.

The primary production equipment for electrolytic aluminium is the electrolytic cell. The production process uses alumina as the raw material, fluoride salts as the flux, and carbon materials as the conductor. This generates large amounts of fluoride and dust.

The use of polyester needle-punched felt bag filters can effectively control flue gas pollution from the electrolytic cell.

The use of high-temperature, corrosion-resistant glass fibre filters in equipment such as smelting furnaces, precious aluminium furnaces, anode furnaces, flash furnaces, submerged arc furnaces, and fluidised bed furnaces used in nonferrous metal smelting can purify flue gas and recover precious metals.

4. Air filtration in the chemical industry

The main pollution in the chemical industry comes from powdered products produced by aerogels during high-temperature production. These products, such as black carbon and melamine, are mainly collected through bag filters.

5. Air filtration in machinery, transportation, road construction, grain, wood processing and other industries

Casting, sandblasting, and spray painting in the machinery industry, as well as painting and cupolas in automobile, bicycle, and motorcycle manufacturing, all generate large amounts of smoke and dust, requiring dust removal.

Asphalt concrete mixing units used in asphalt pavement construction, as well as grain processing, flour processing, feed processing, wood processing, coal, ceramics, tobacco, light industry, textiles, fertilisers, pesticides, and port transportation, also require bag filters.

Boiler smoke is a major source of air pollution. Power plant boilers and heating boilers currently primarily utilise electrostatic precipitators and cyclone dust collectors, but these are gradually being replaced by bag filters.

With increasingly stringent national emission standards, bag filters will play a greater role in this area.

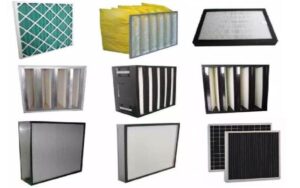

6. Cleanroom air filtration

For ordinary air conditioning systems, one coarse air filter, or one coarse air filter and one medium air filter, is sufficient. Cleanroom air conditioning systems, however, require three filters: coarse and medium air filters, plus a high-efficiency air filter.

Cleanroom air conditioning systems are generally divided into two categories: industrial cleanrooms and biological cleanrooms. Industrial cleanrooms are primarily used in production processes that require extremely high air cleanliness. Biological cleanrooms have requirements not only for indoor dust concentration but also for bacterial counts.

High-efficiency filters can also remove bacteria attached to dust particles. Similar requirements also exist in hospital operating rooms and special care areas, pharmaceutical factories, and biological laboratories.

7. Indoor air filtration

The popularity of home air conditioners is increasing year by year. The filter material they use is mostly ordinary plastic woven mesh, which has large pores and can only filter out larger dust particles.

Indoor air purifiers are another potential market for air filters. People spend 90% of their time indoors, but indoor air pollution can be far more severe than outdoor air.

Indoor air can contain smoke, mold spores, bacteria, fibres, dust particles, and more. Using an air purifier is an effective way to remove indoor pollutants.